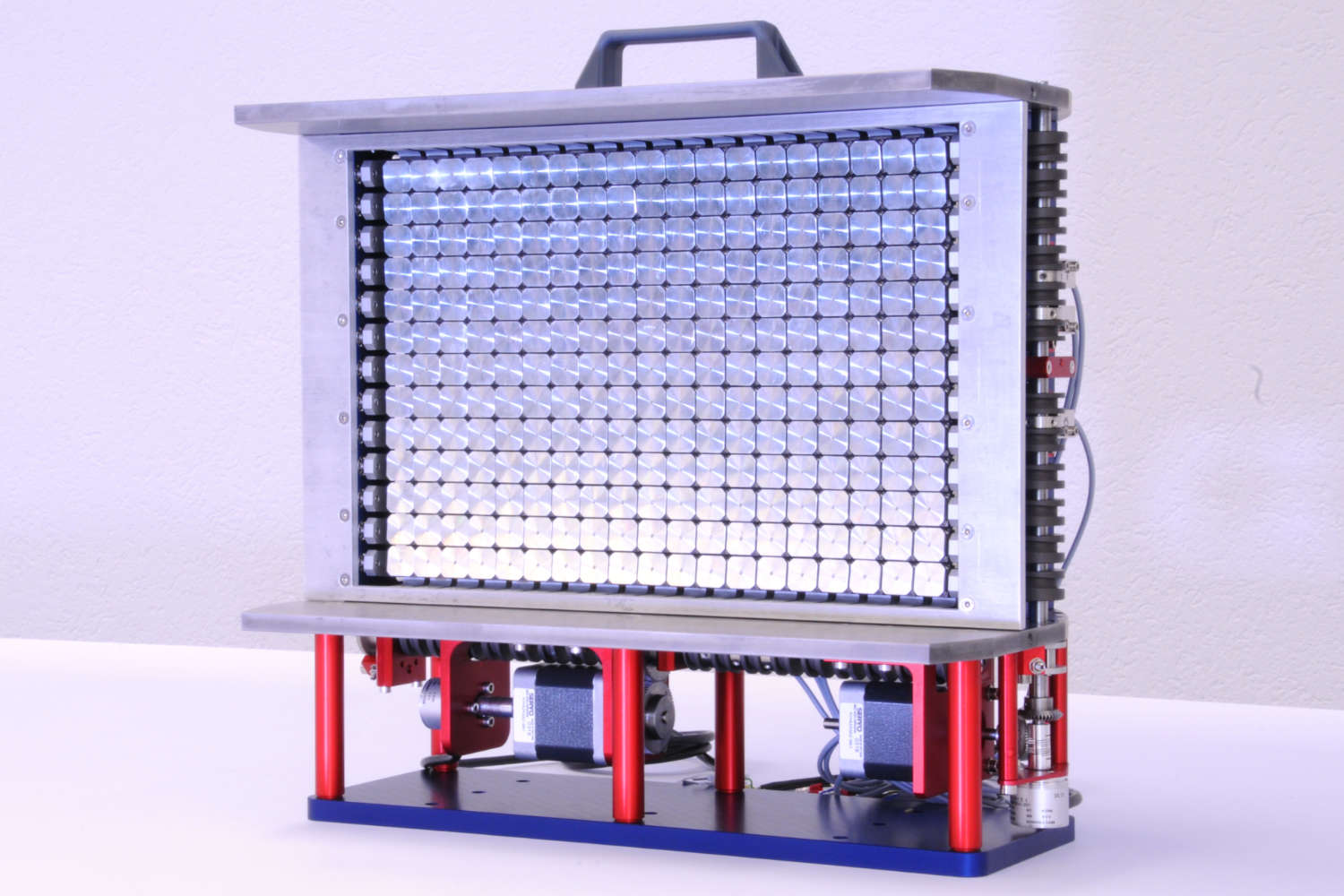

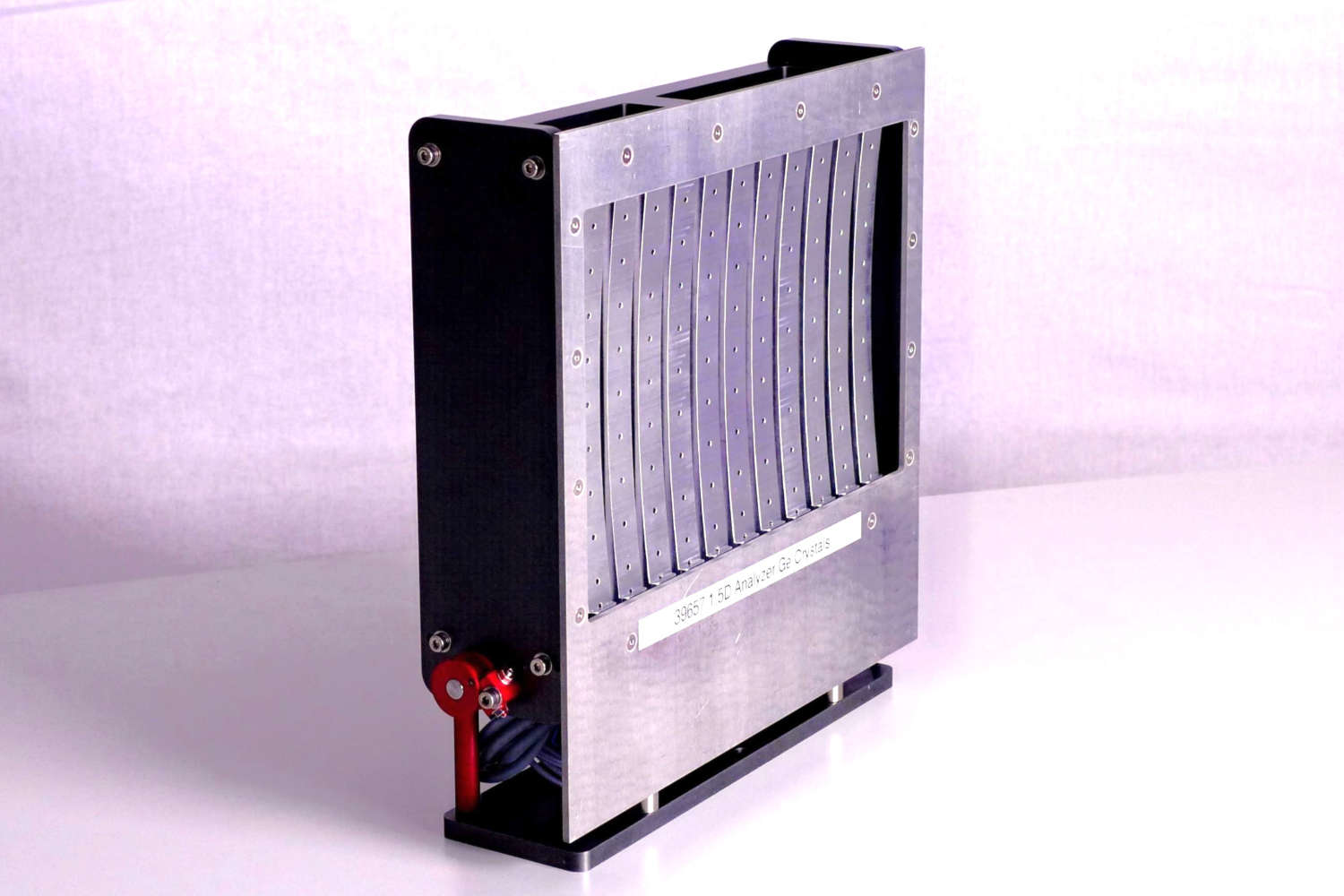

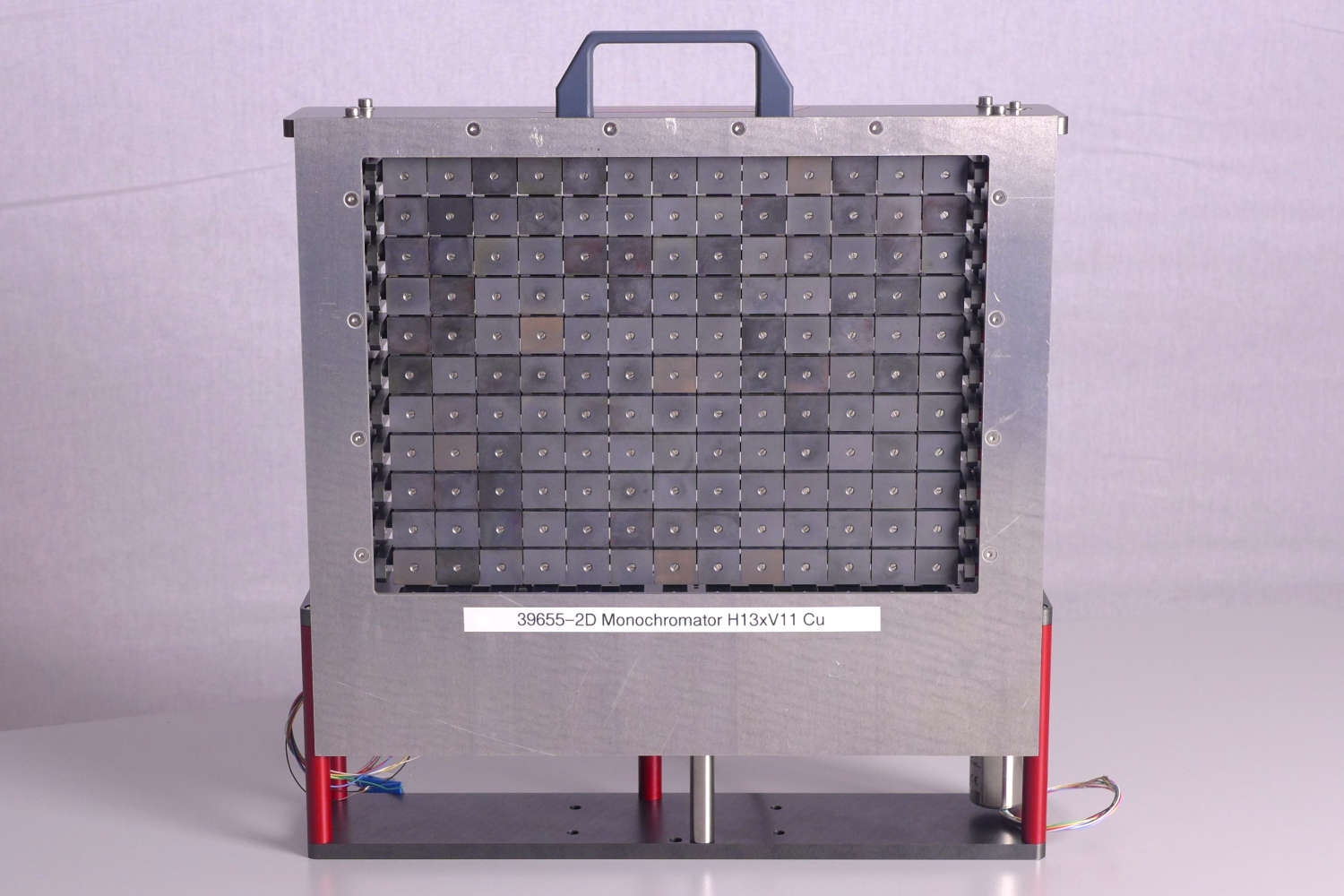

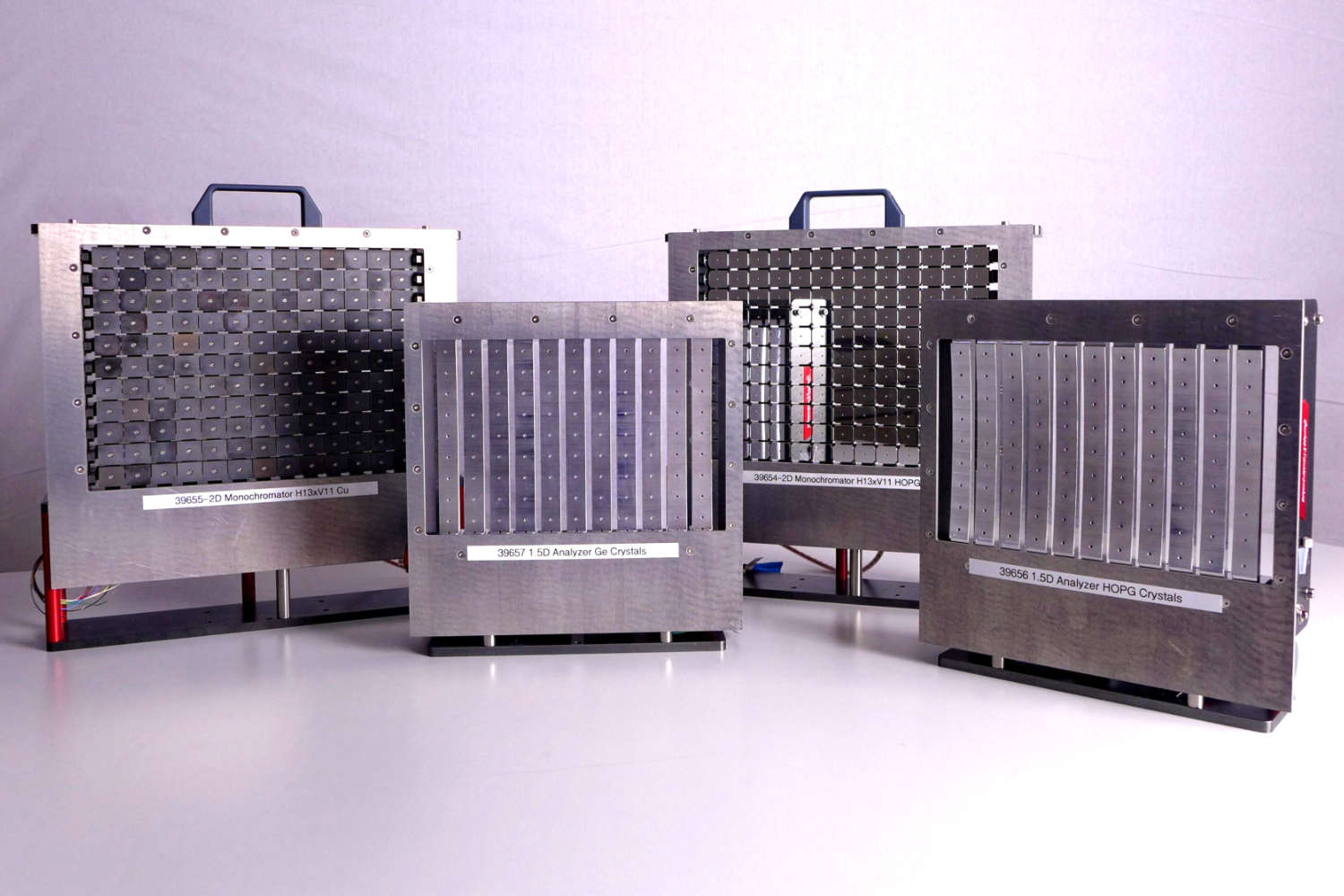

Two-dimensional focusing arrays enable precise beam shaping by tilting each crystal in both vertical and horizontal directions. With high angular accuracy, low-background mounting, and integrated motion control, the system ensures optimal Bragg alignment and beam intensity. SwissNeutronics’ customizable platform suits diverse experimental setups and advanced neutron optics applications.

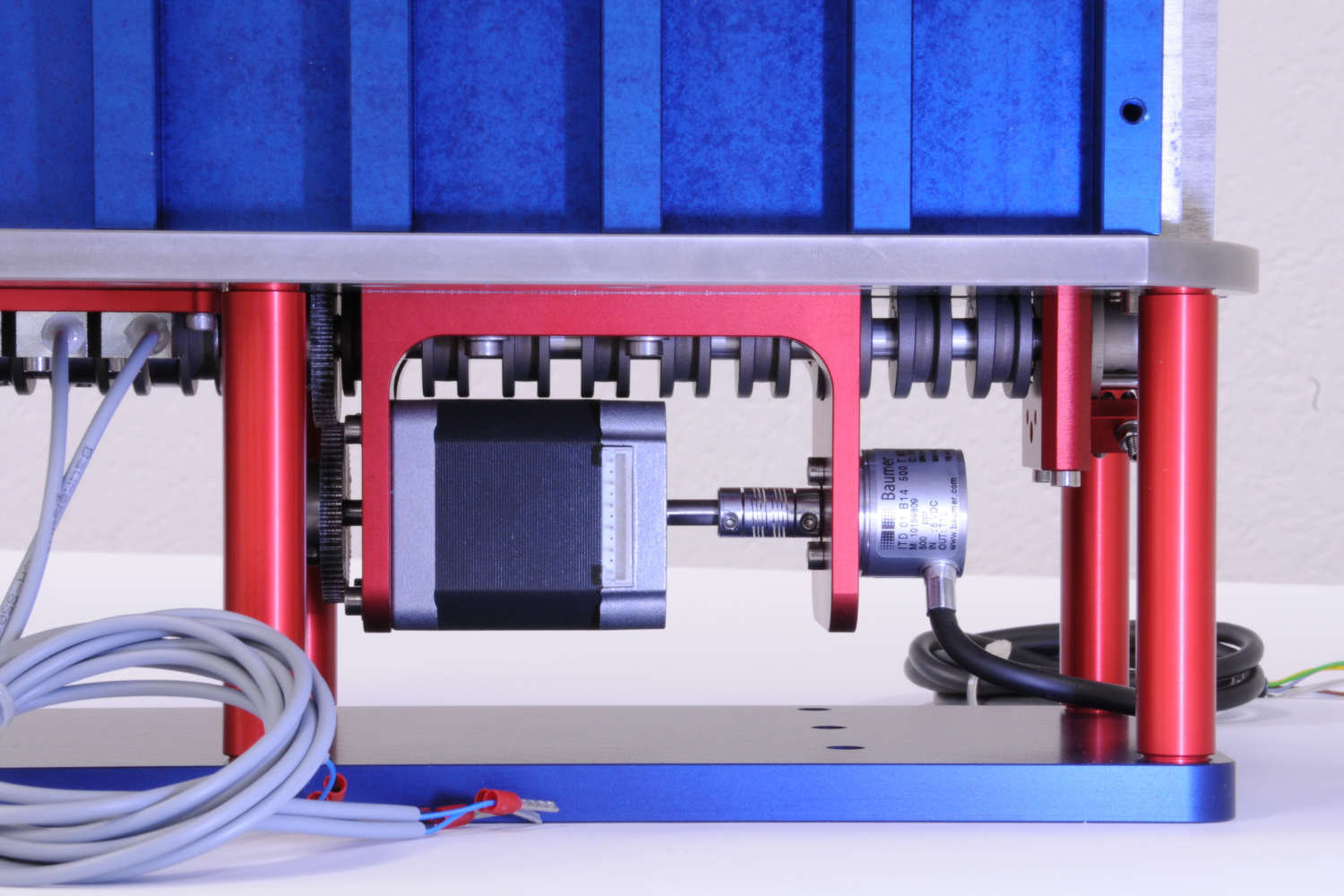

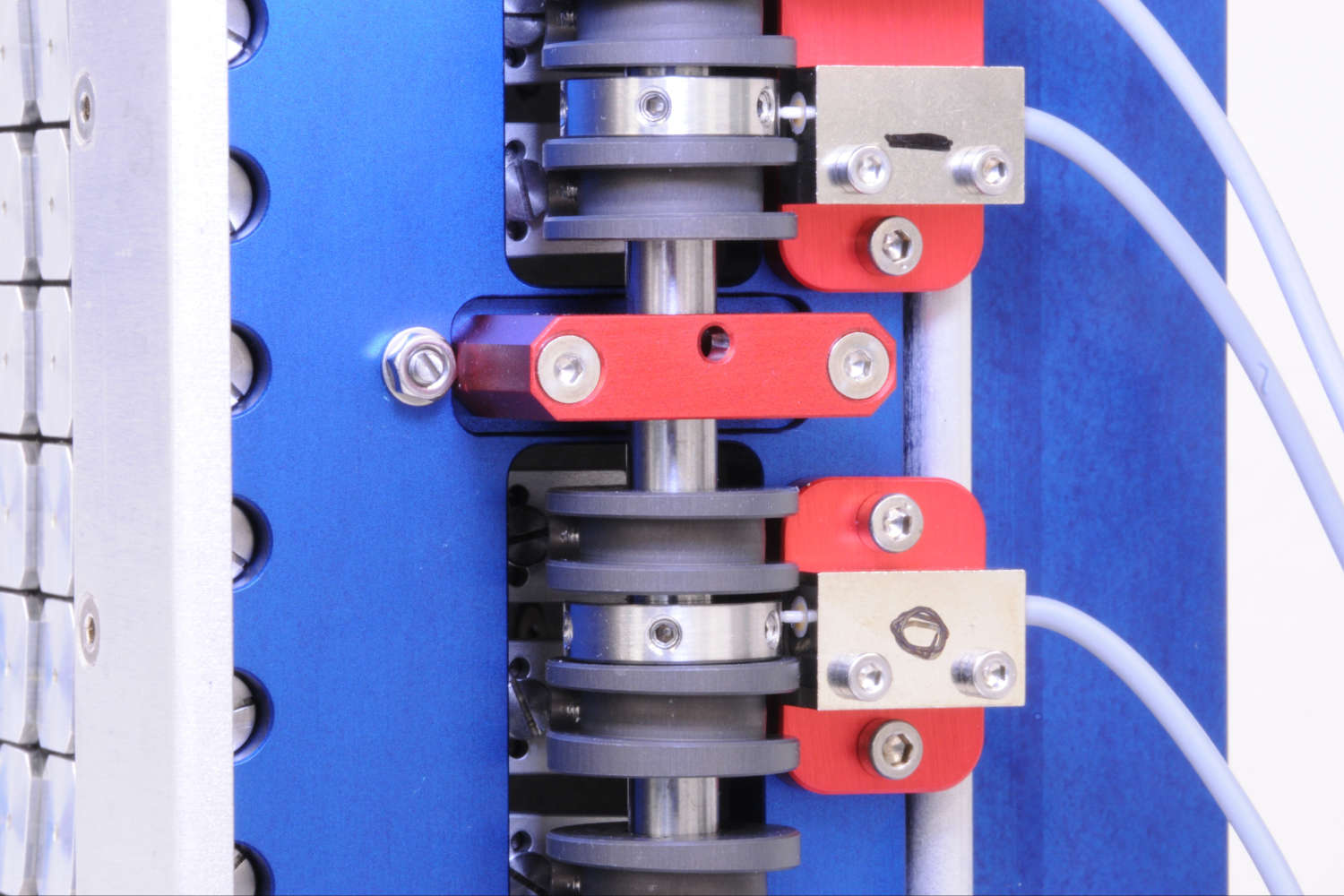

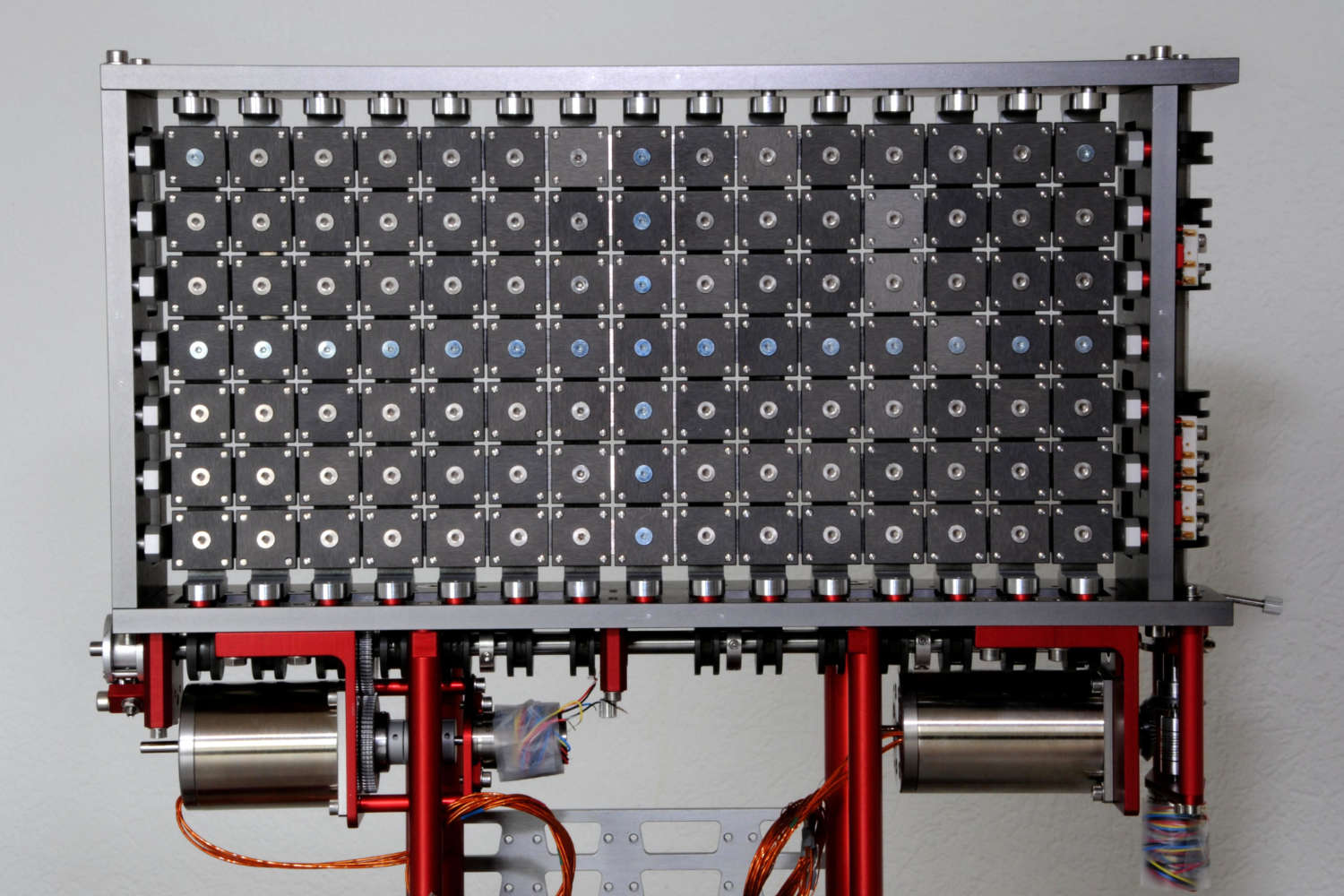

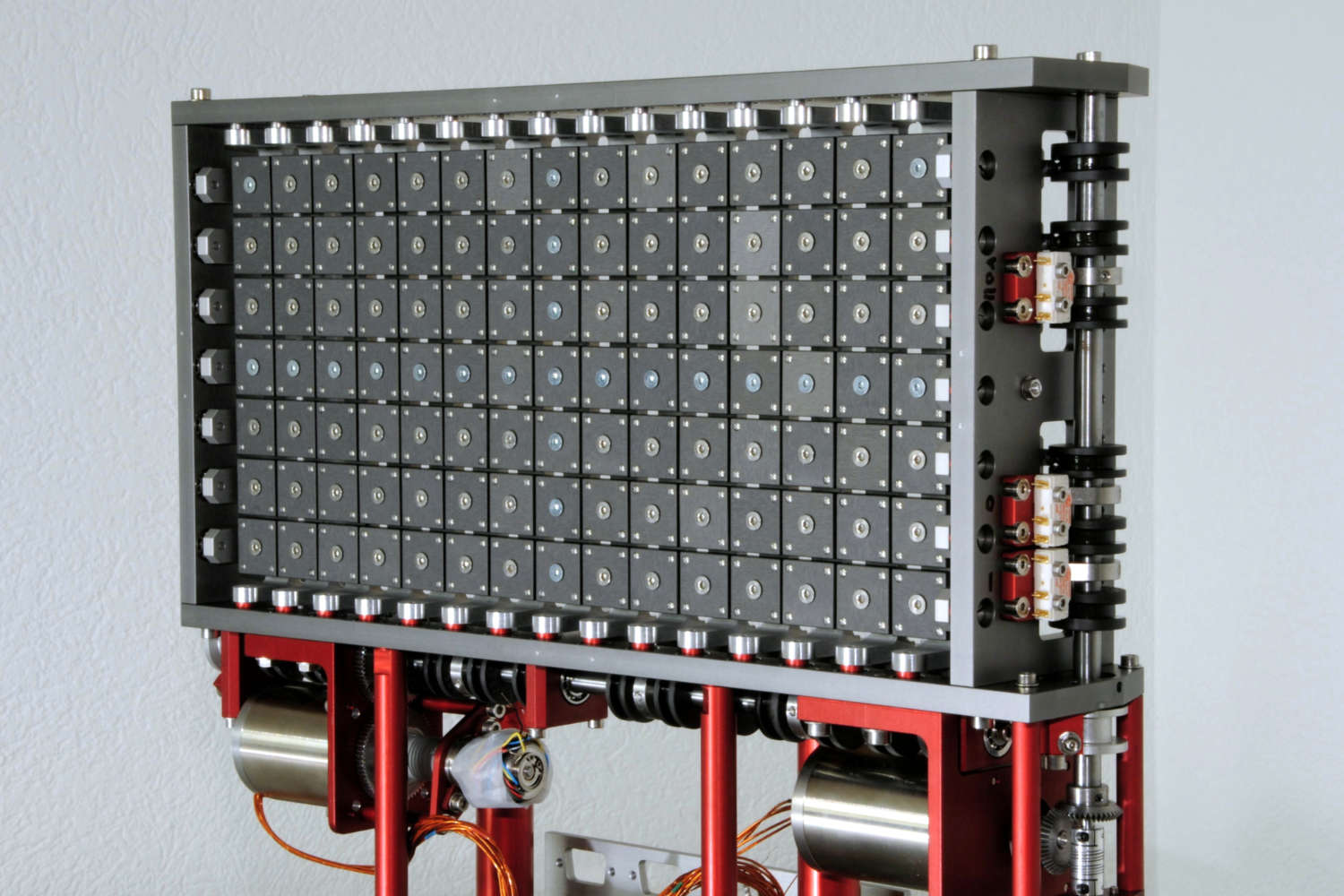

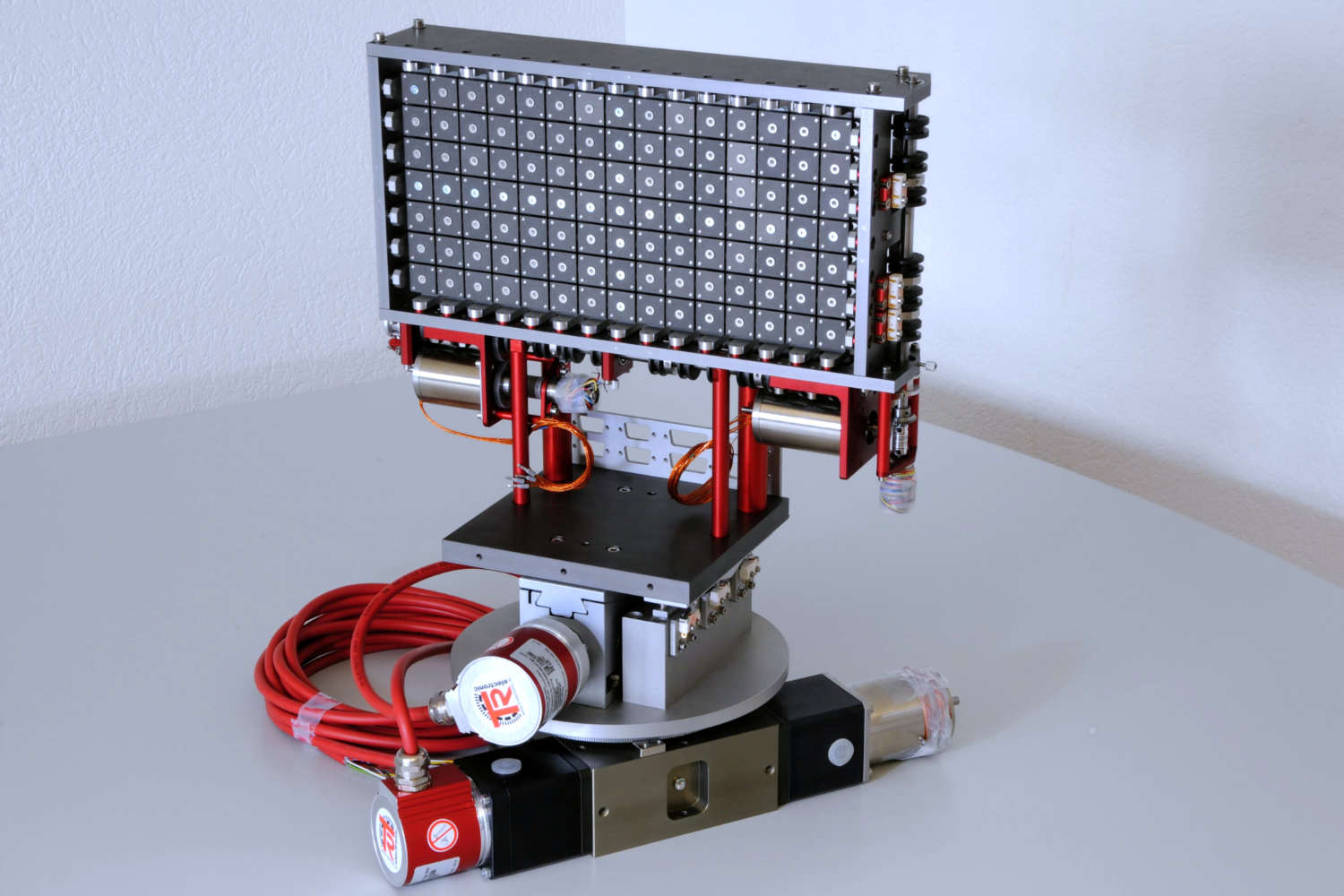

Two-dimensional focusing arrays are precision-engineered systems designed to optimize beam shaping in both vertical and horizontal directions. Each crystal element within the array is individually adjustable, allowing fine-tuned alignment to the Bragg condition across the entire surface. This ensures maximum beam intensity and resolution for demanding neutron optics applications. The system architecture supports independent angular control in both axes, typically achieved through motorized actuators combined with high-resolution feedback mechanisms such as encoders or resolvers. SwissNeutronics offers a standardized yet highly customizable design platform that integrates this advanced mechanism, enabling adaptation to a wide range of experimental geometries.

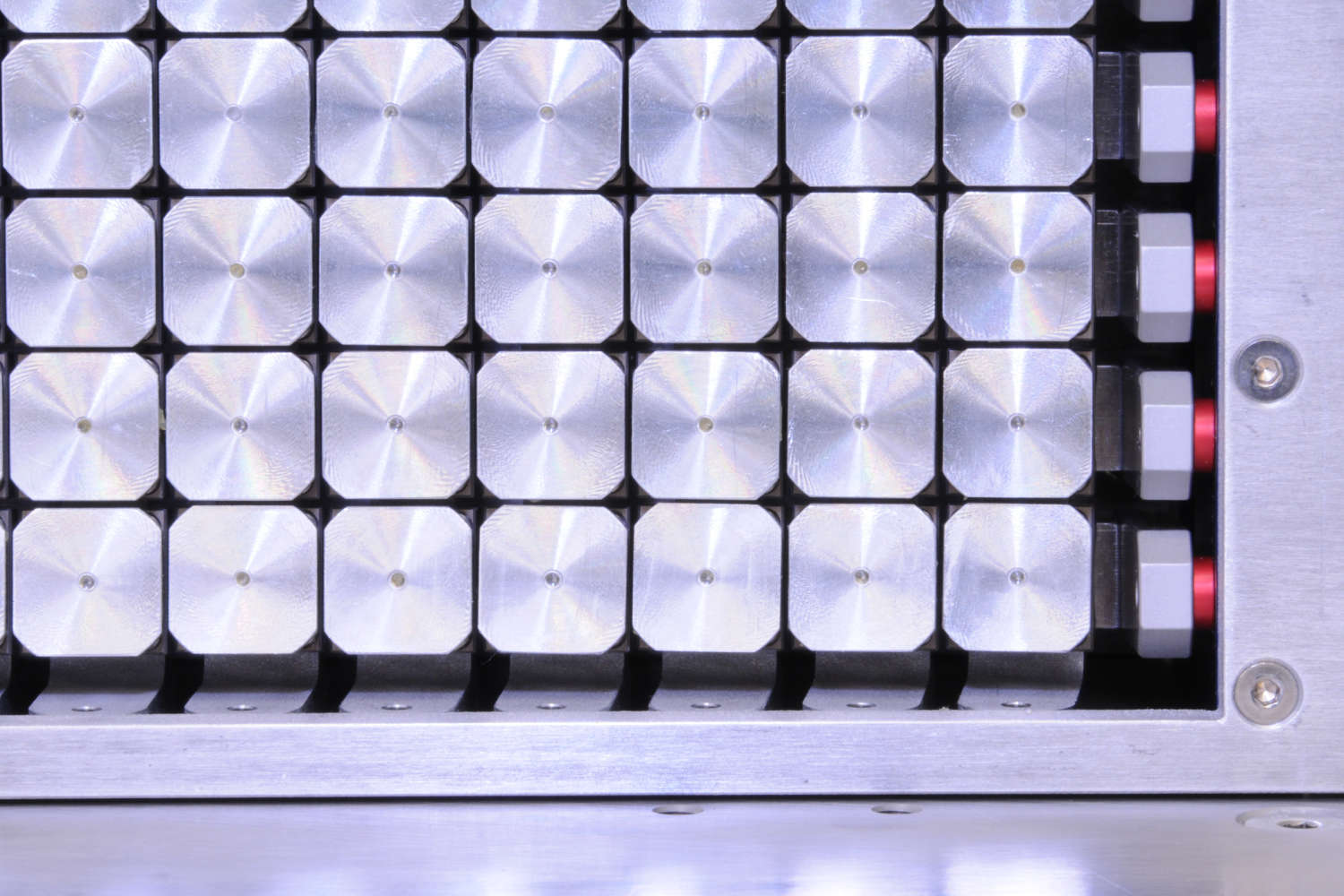

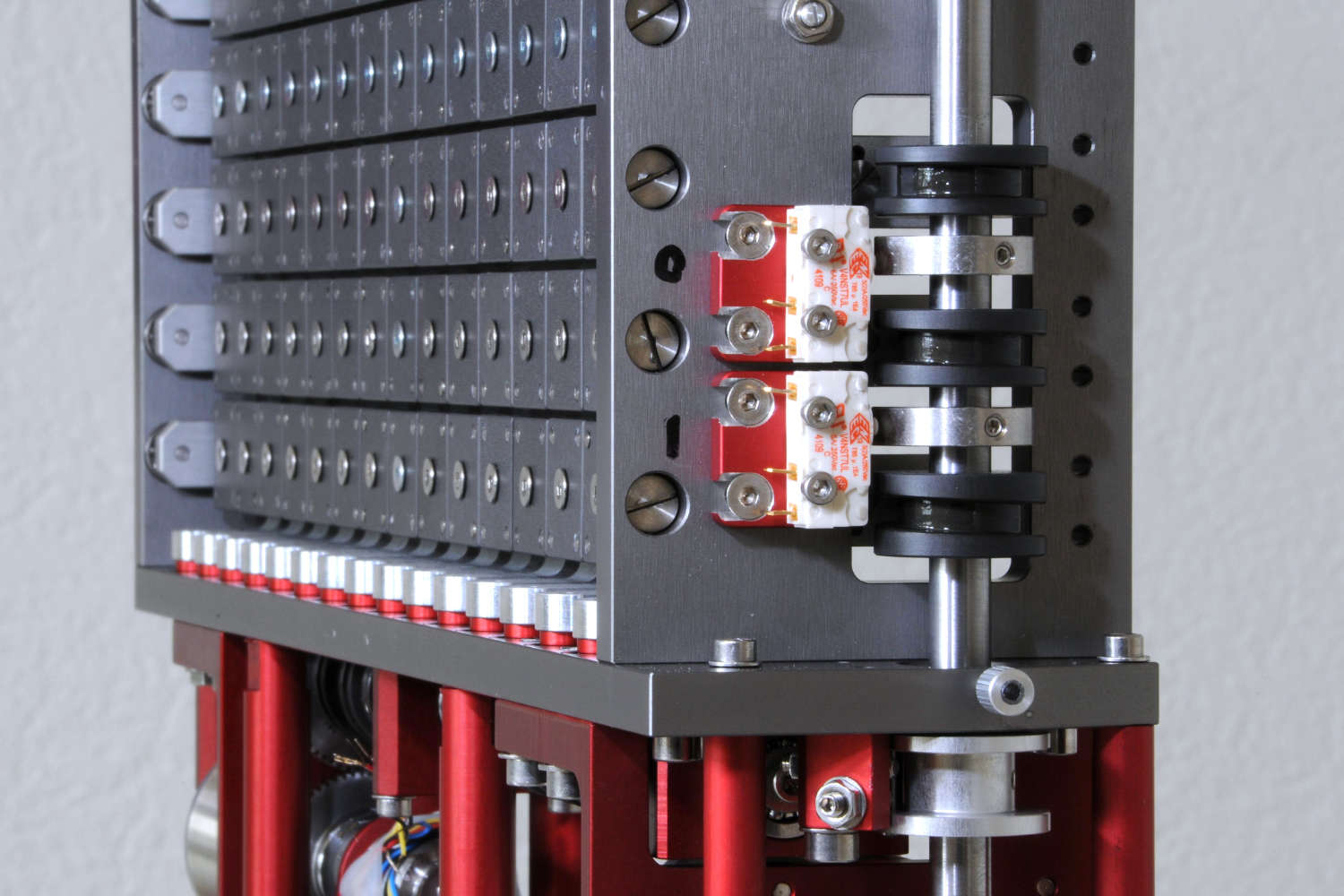

The system delivers high angular precision, with absolute accuracy better than 0.05° RMS and repeatability within ±0.02°. Its beam-compatible mechanical design minimizes material in the neutron path, reducing scattering and absorption. Crystal mounting options include sintered B₄C platelets to suppress background radiation and soldered crystal holders for enhanced stability. Integrated motion control features stepper motors and limit switches for reliable positioning, while compatibility with goniometer stages allows multi-axis angular adjustments. Flexible mounting configurations and optional enhancements—such as shielding elements and integrated guide fields—further expand the system’s versatility, making it ideal for customized, high-performance neutron instrumentation.

Technical highlights

- High Angular Precision

– Absolute accuracy: < 0.05° (RMS)

– Repeatability: < ±0.02° - Individual Crystal Alignment

Provision for precise adjustment of each crystal element to optimize focusing geometry - Beam-Compatible Mechanical Design

Mechanism engineered with minimal material in the neutron beam path to reduce scattering and absorption - Low-Background Crystal Mounting

– Sintered B₄C platelets positioned between crystals and holders to suppress background radiation

– Soldering of crystals to sample holder - Integrated Motion Control

Fully equipped with stepper motor, encoder or resolver, and home/limit switches for reliable and accurate positioning - Goniometer Integration

Designed for integration with goniometer stages to enable multi-axis angular control - Customizable Features & Mounting Options

– Flexible mounting configurations to support various experimental setups

– Optional enhancements: shielding elements, integrated guide fields, and other application-specific components