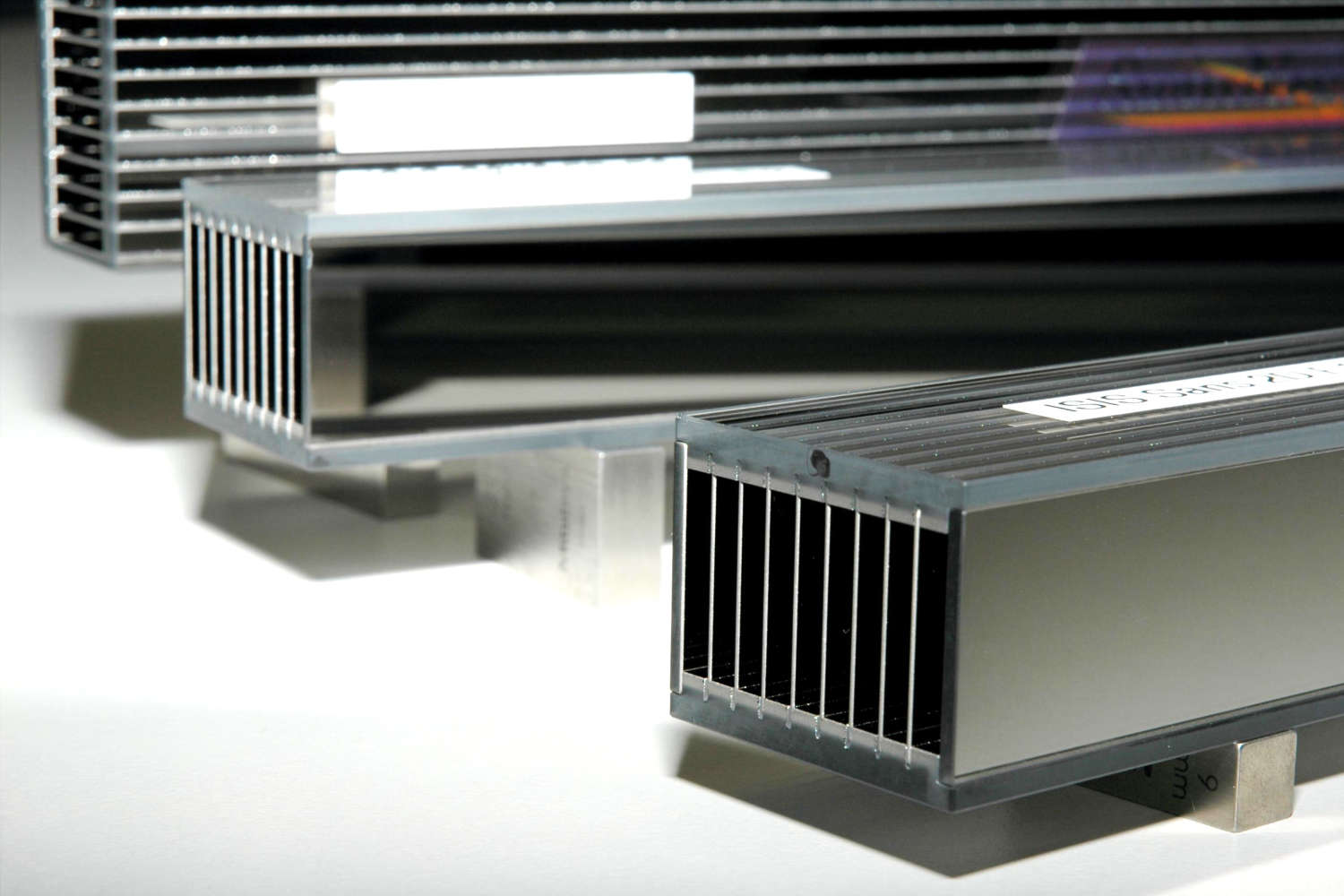

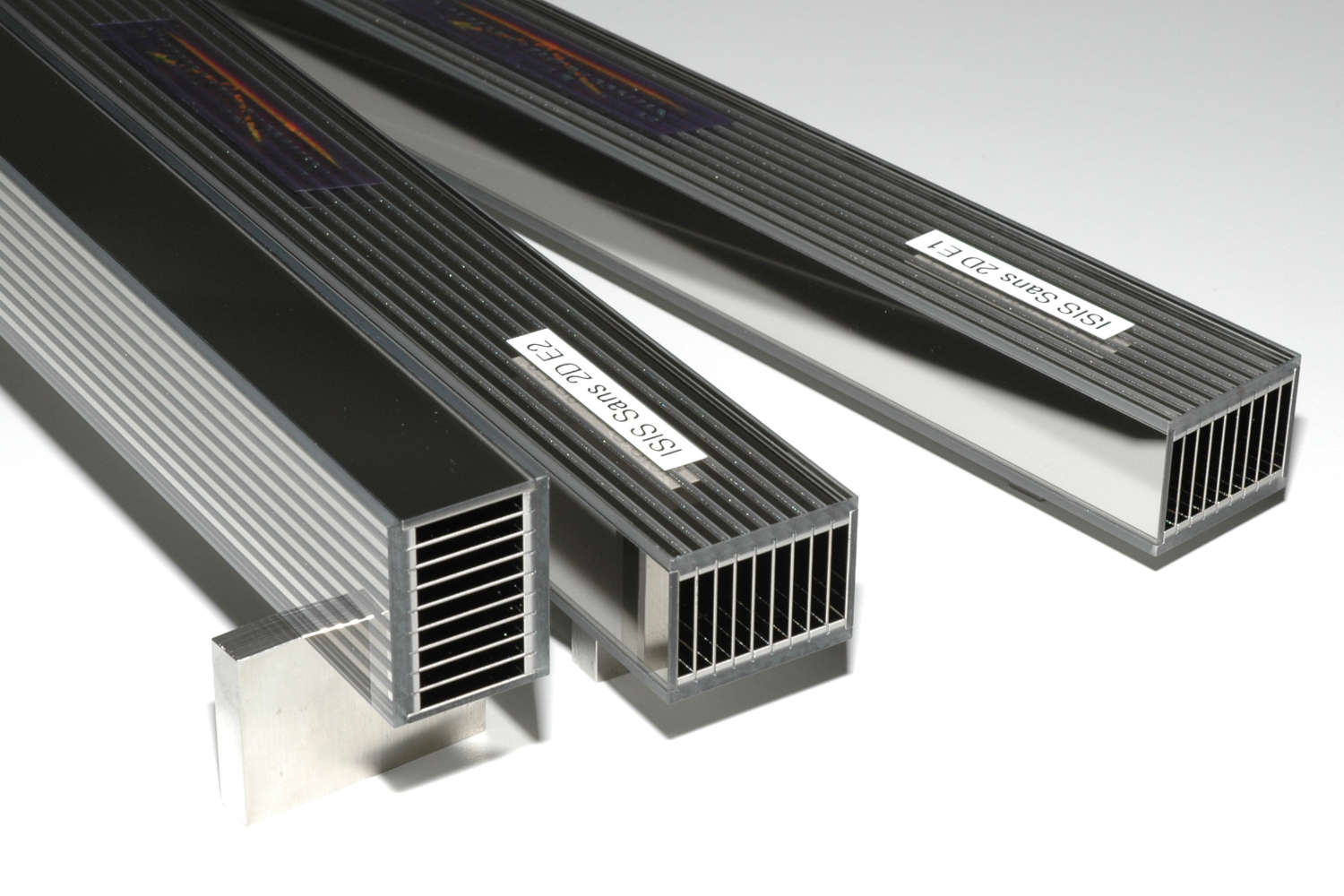

From standard to the “finest arts” – SwissNeutronics manufactures neutron guides in a wide range of dimensions, materials, and complexities—from standard designs to highly customized solutions. Combining high-performance supermirror coatings with exceptional mechanical precision, these guides ensure excellent neutron transmission and are suited for demanding scientific applications.

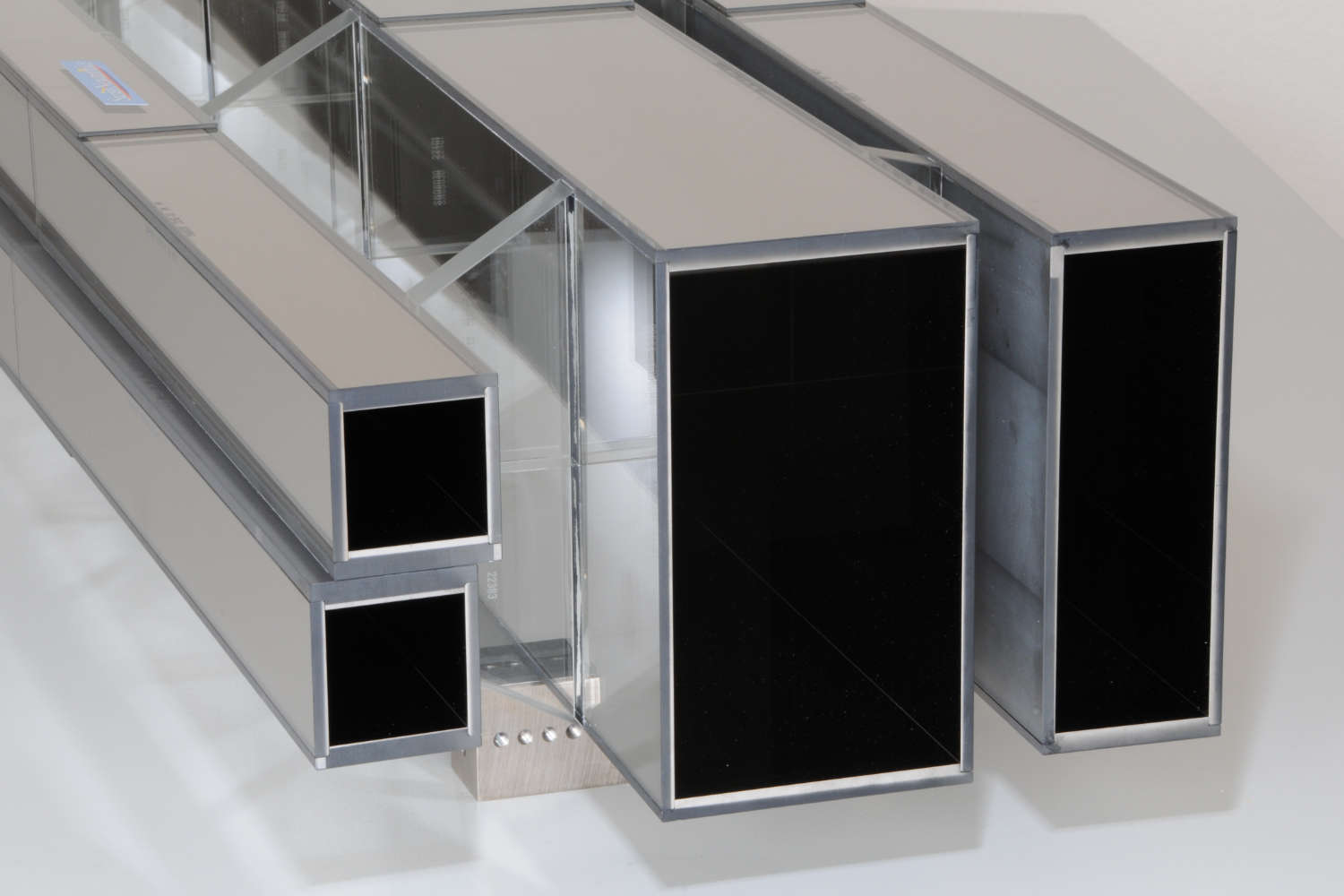

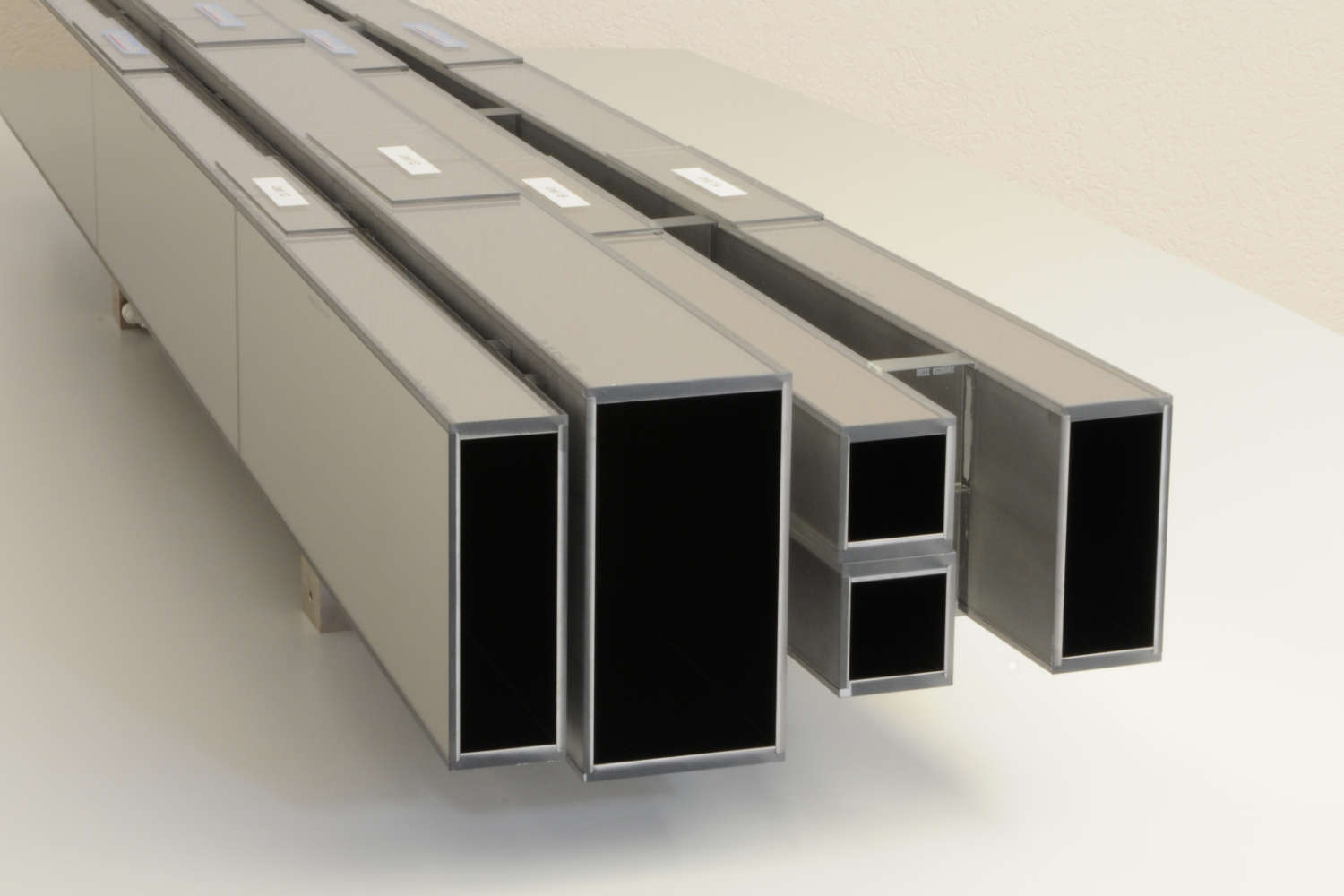

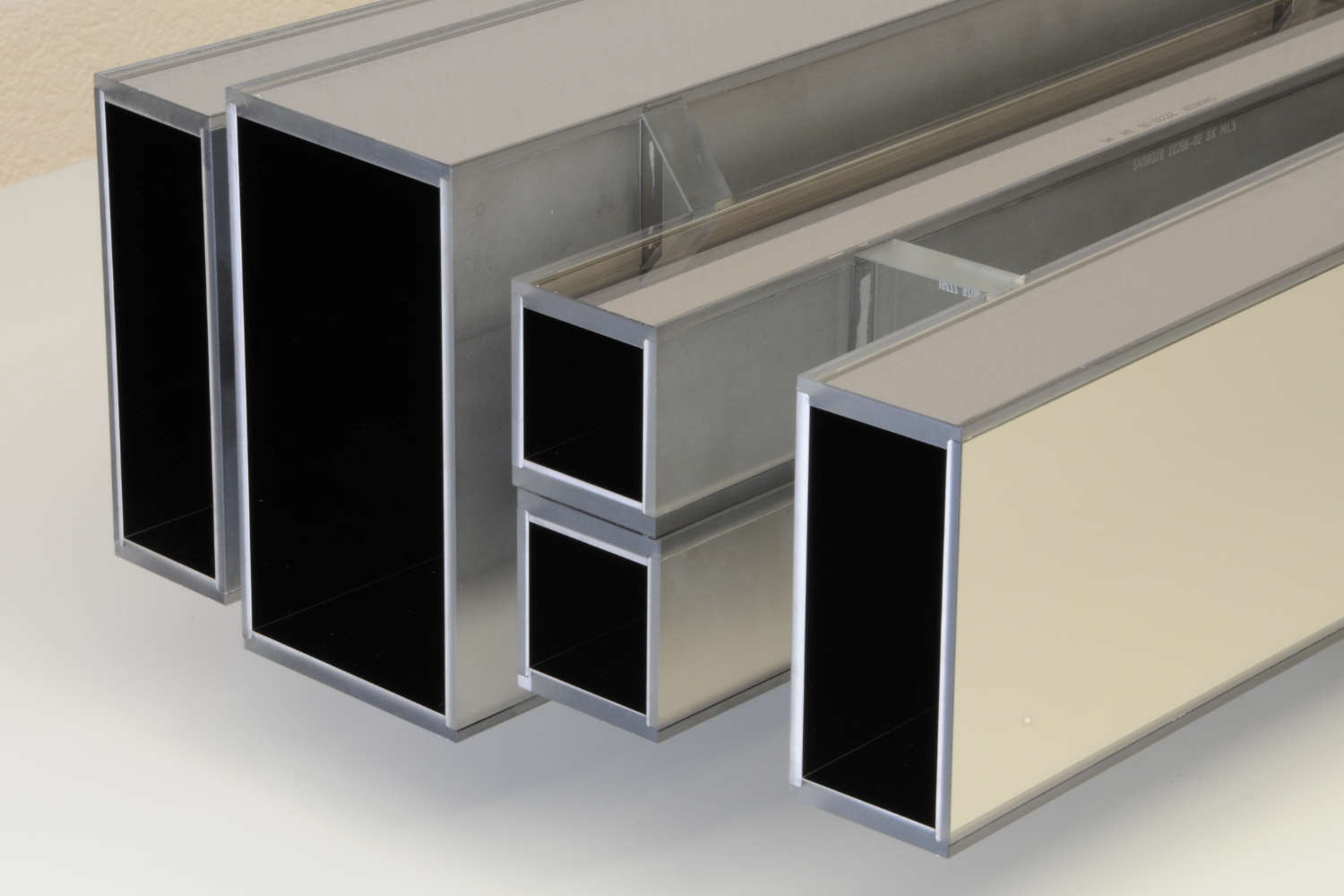

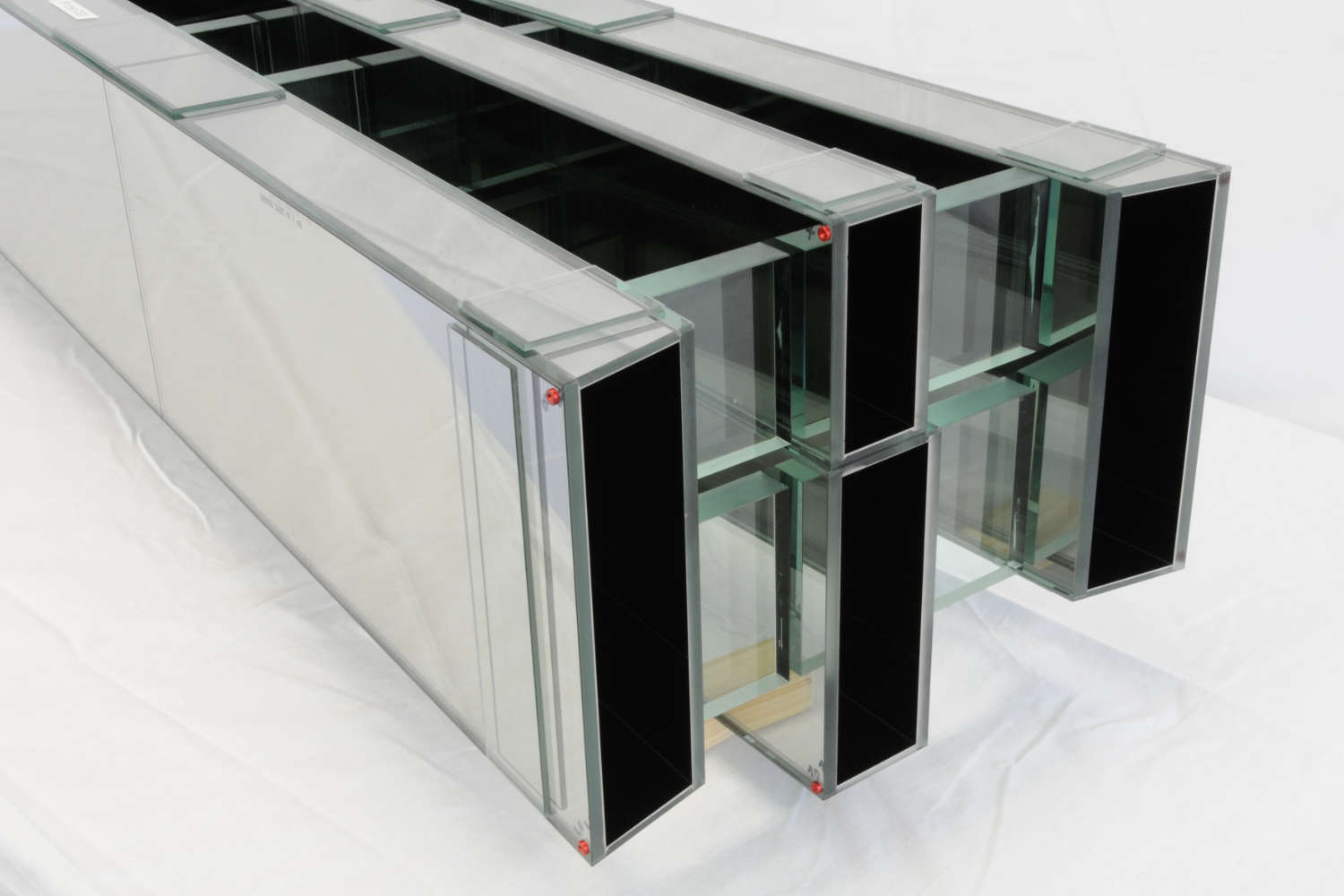

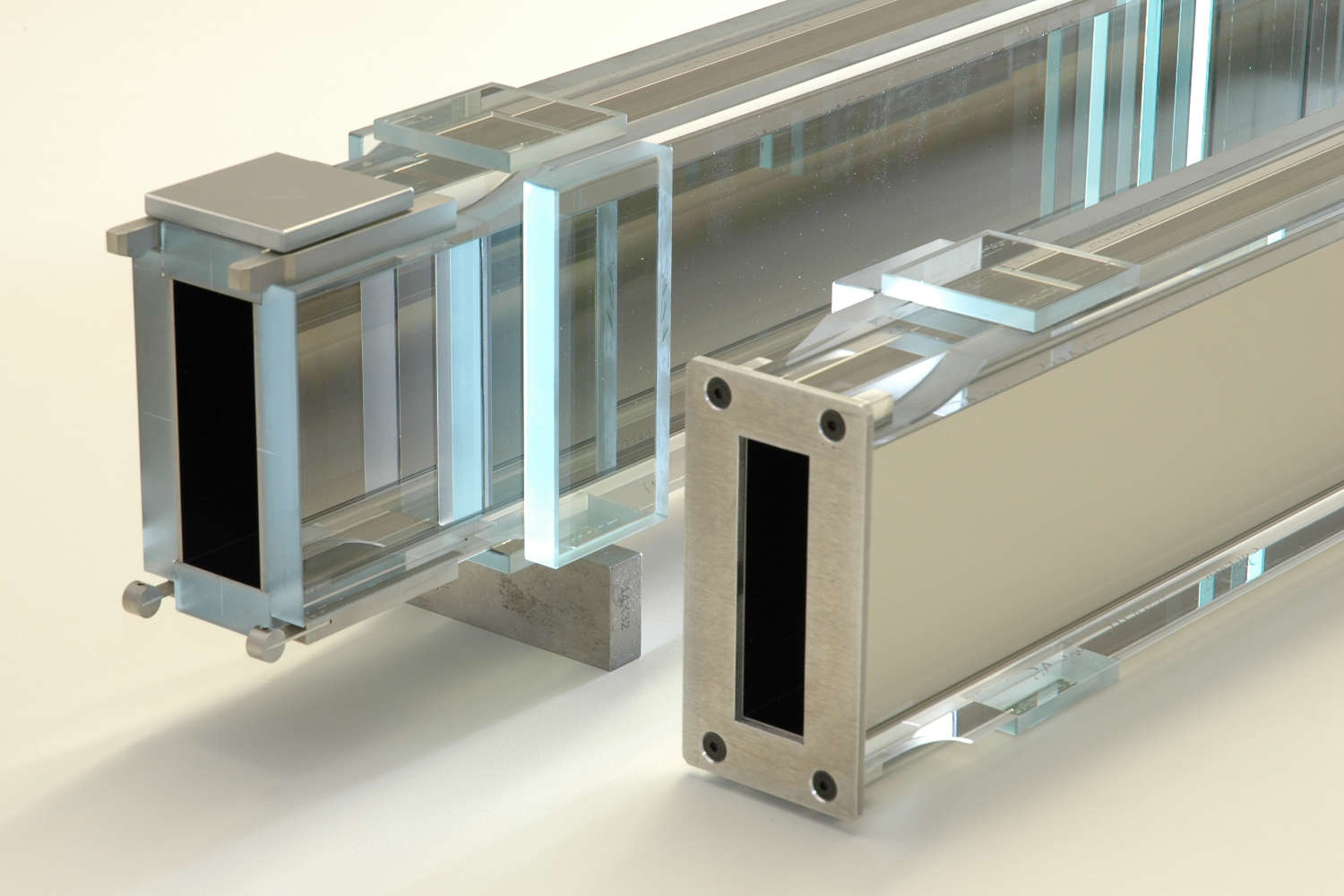

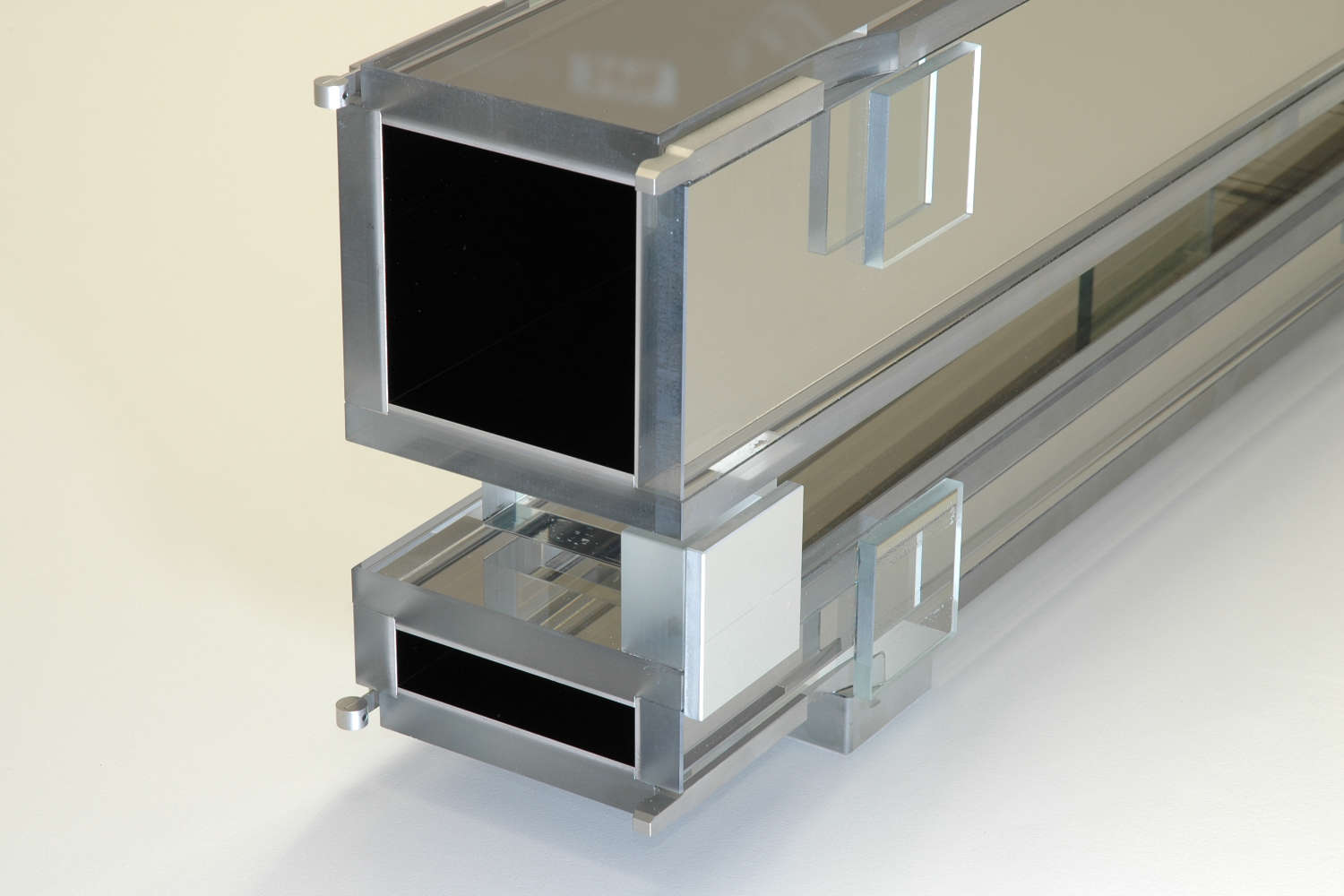

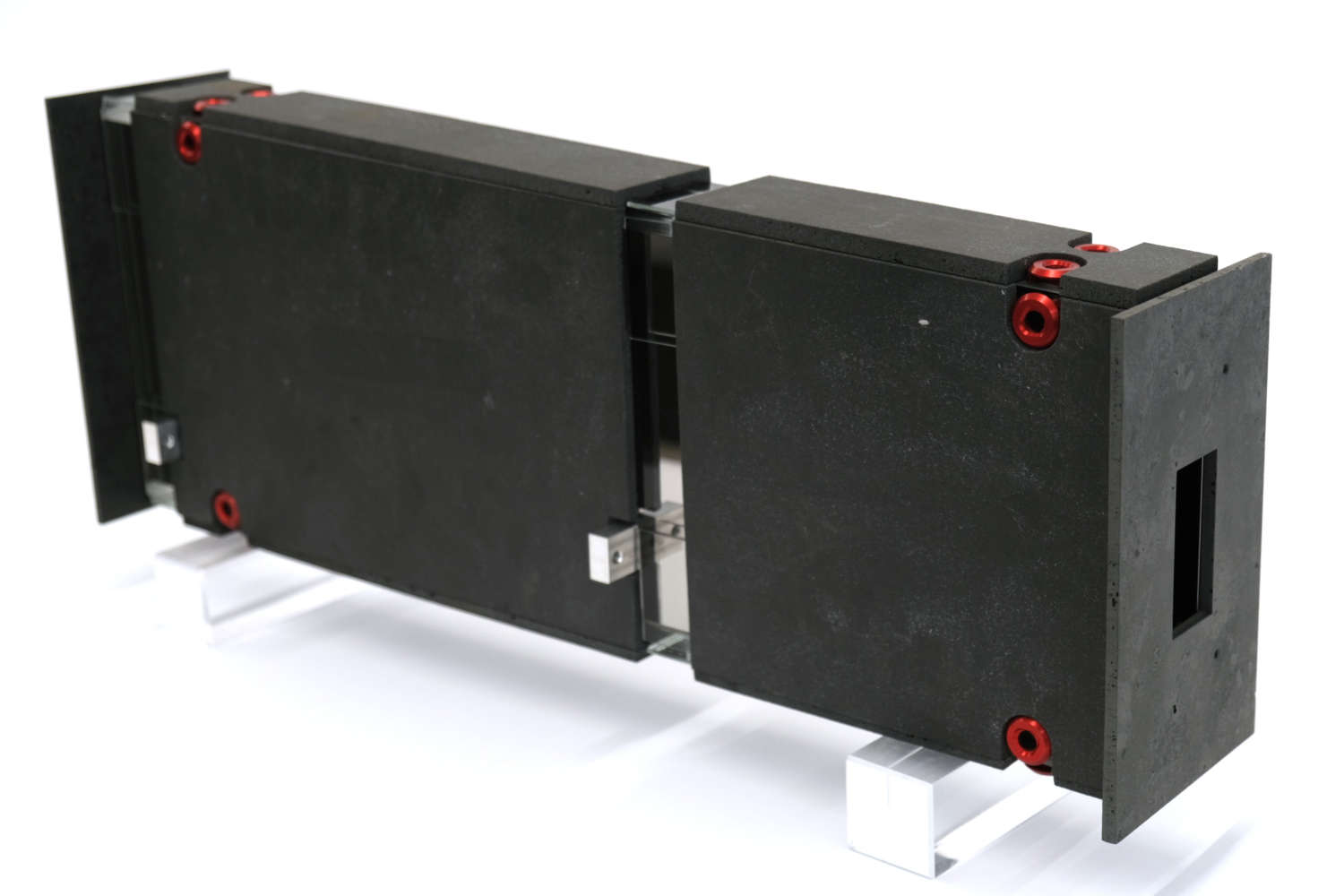

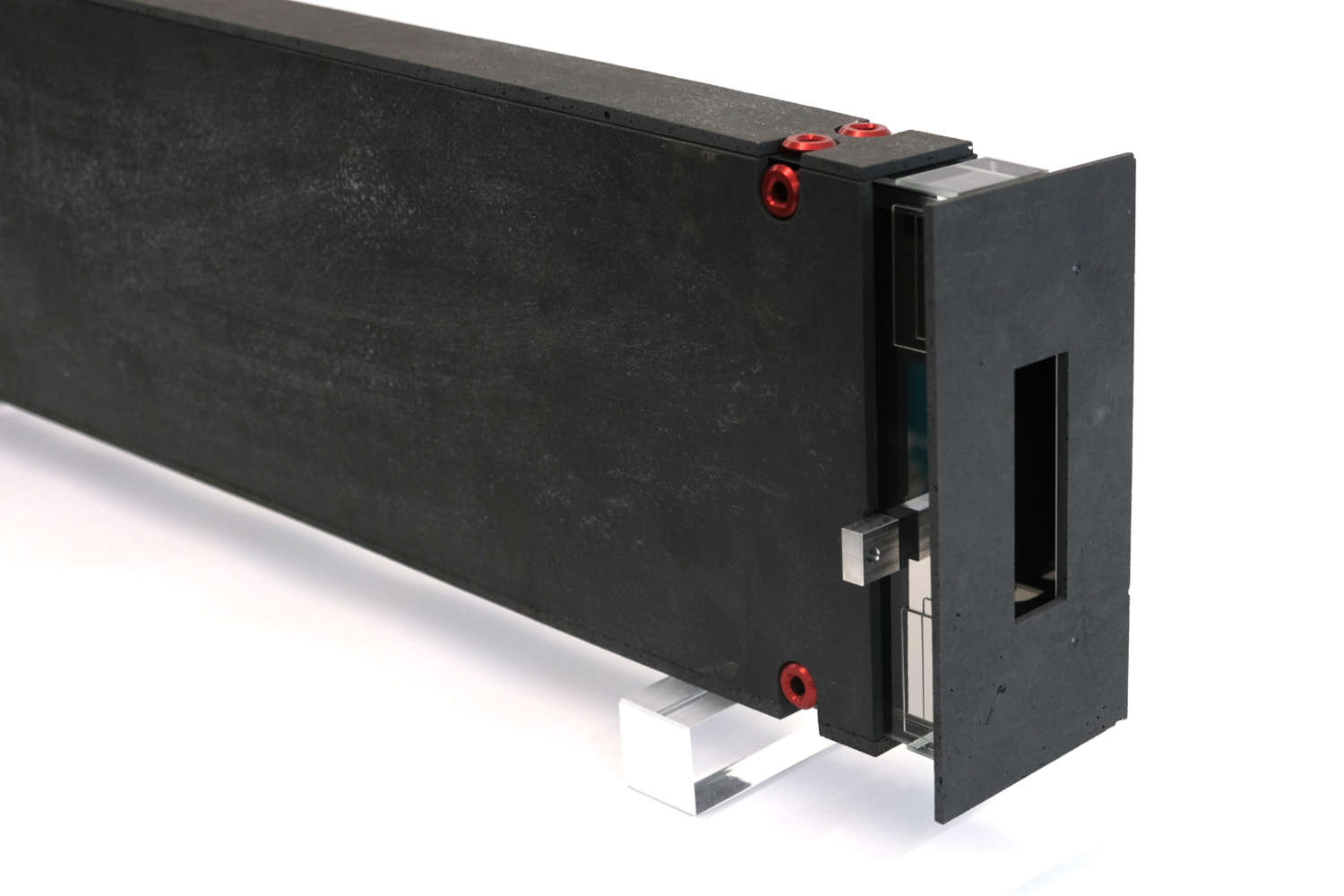

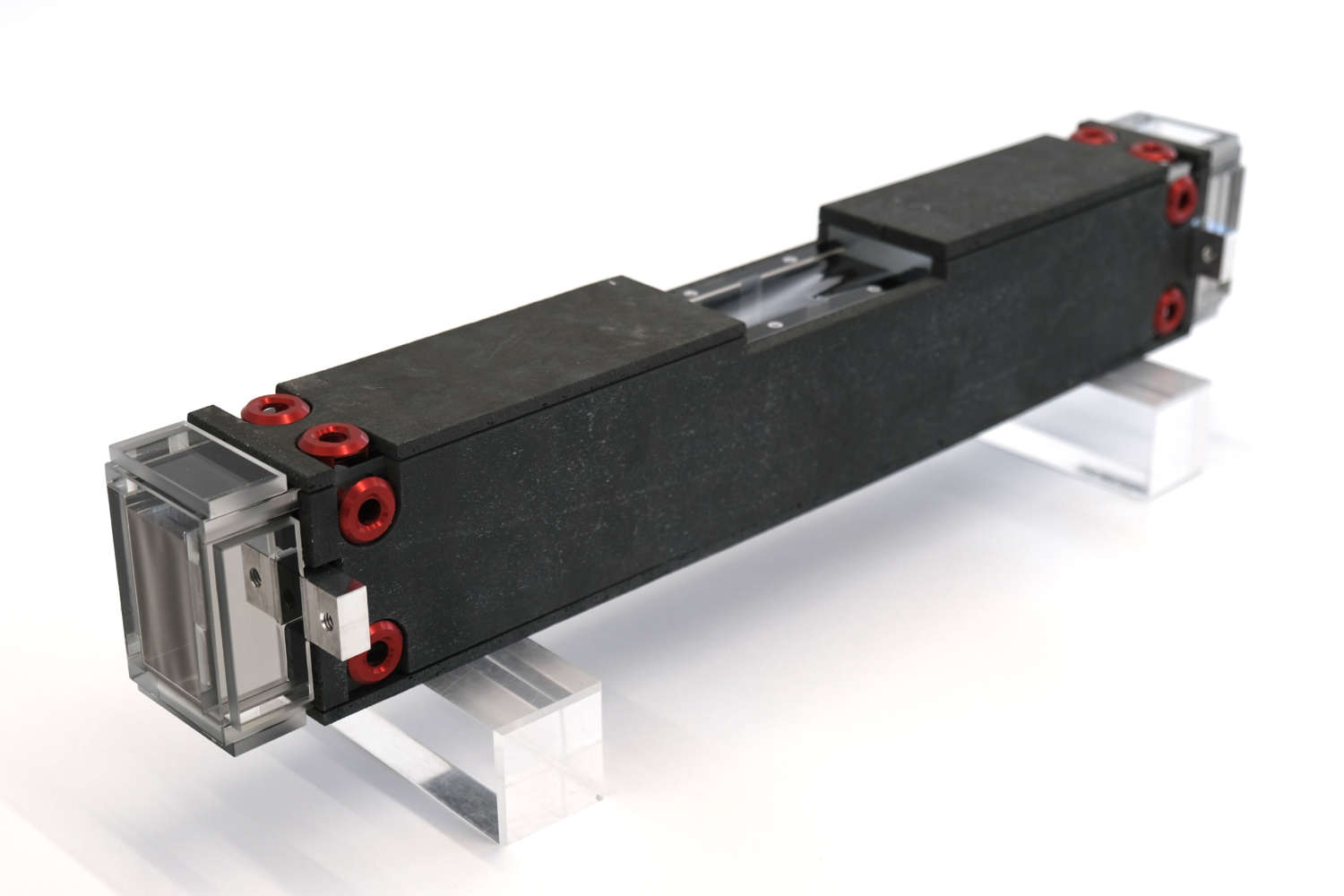

The fabrication of neutron guides at SwissNeutronics is carried out with meticulous precision and in strict adherence to the company’s high-quality standards. Each guide cross-section is defined using finely ground substrates, implemented through the innovative trottoir-ruler construction method—an original development by SwissNeutronics. This unique design ensures exceptional mechanical stability and long-term reliability, as the geometry remains unaffected by irradiation-induced degradation of adhesives, even over several decades of operation.

Supermirror coatings are applied using advanced DC magnetron sputtering techniques. This sophisticated deposition process achieves outstanding neutron reflectivity while maintaining ultra-smooth interfaces. Internal stresses within the multilayer coatings are carefully controlled and minimized to prevent delamination and to ensure the structural integrity of the guide system under demanding conditions.

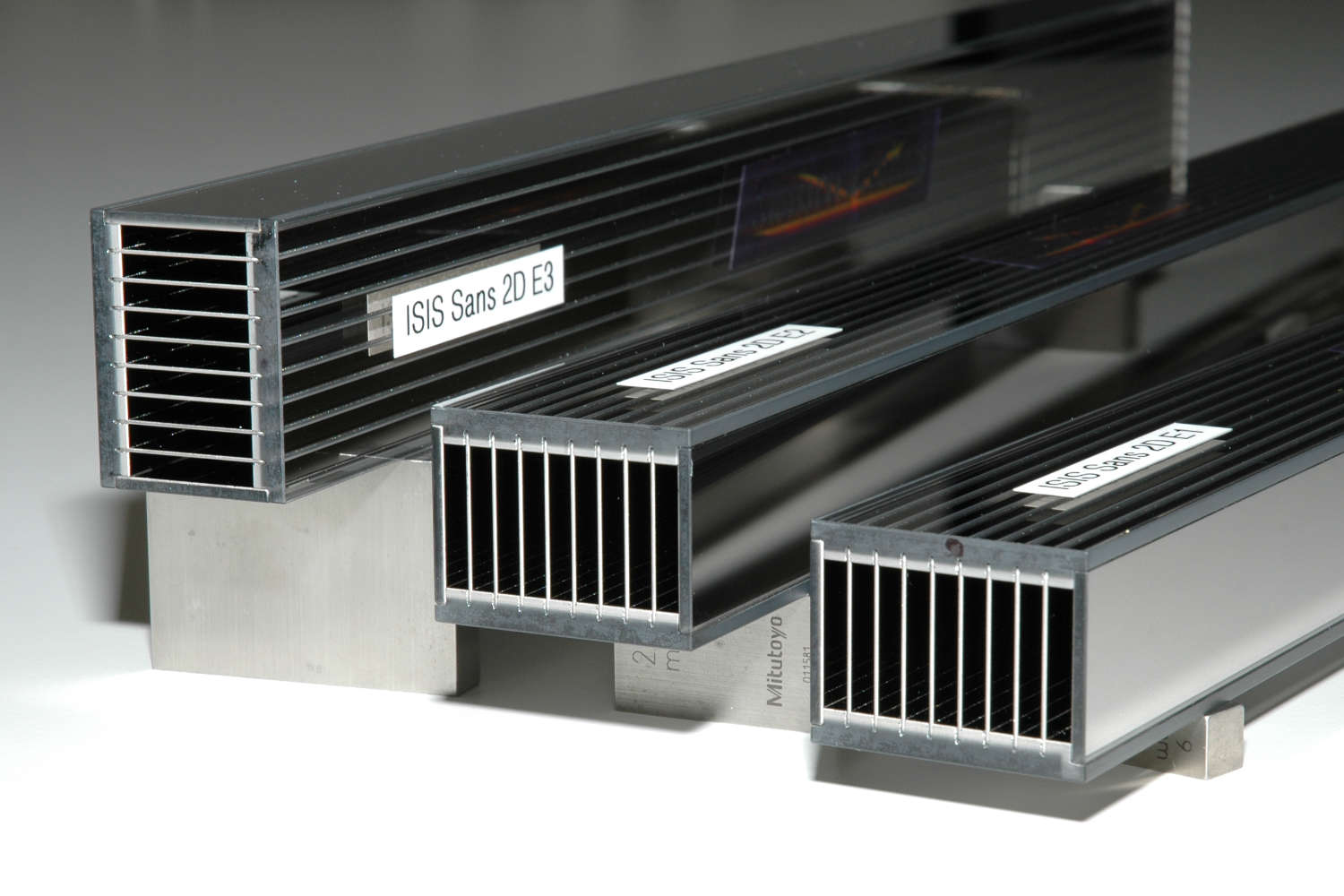

Every neutron guide undergoes rigorous quality assurance as part of a comprehensive quality control management system. This includes full inspection of each guide unit and complete traceability of every individual substrate used in the assembly. Such thorough procedures guarantee consistent performance, reproducibility, and reliability across all production batches.

SwissNeutronics’ commitment to precision engineering, innovation, and quality assurance ensures that its neutron guides meet the highest standards required for advanced neutron research and facility operations worldwide.

Technical highlights

- Complex geometries

guide splitters, truly curved, benders, focusing guides - Profile shapes

curved, elliptic, parabolic, octahedral cross-sections - Materials available

float glass, Borofloat® 33, N-BK7, silicon, aluminum, copper - Size

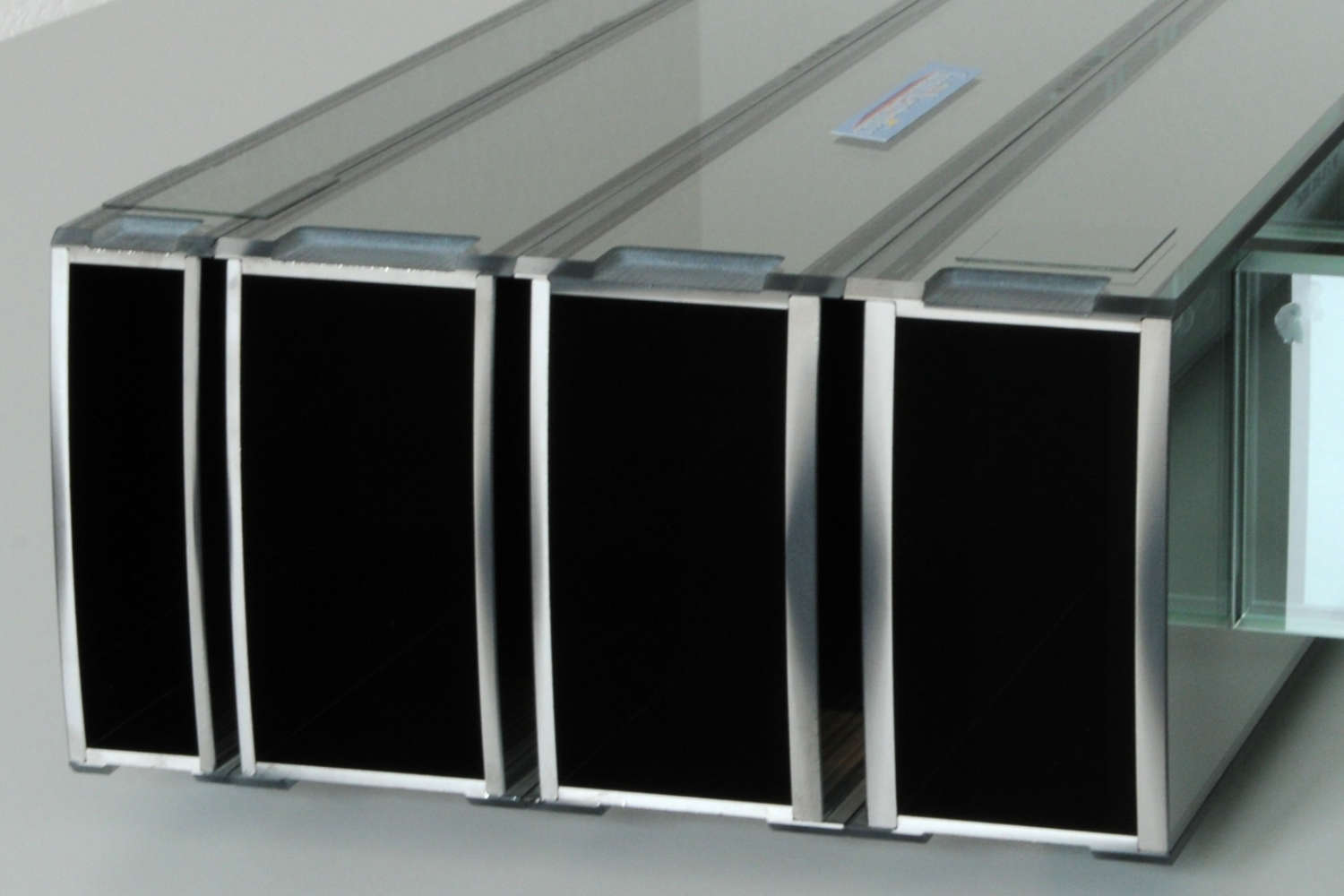

– Guide unit lenght typically between 1.5 m and 3 m

– Cross-section from a few millimeters up to 400 mm × 500 mm - Precision

– Cross-section accuracy ±0.02 mm, typically around 0.01 mm RMS (dependent on cross-section)

– Surface waviness typically < 1.0 × 10⁻⁴ rad (dependent on cross-section) - Vacuum tightness

Leak rate: 1 × 10⁻⁷ mbar·L/s