Competencies and services

Whether according to the drawing or directly from the CAD model: we manufacture precision milling and turning parts as well as ready-to-install mechanical engineering parts and assemblies. Our manufacturing specialists have great know-how in processing special materials such as glass, silicon, GfK or other composite composite materials. Of course, we also work on all common metals. We take care of everything for you – from material procurement to surface treatment and final assembly, including measurement of the components and test protocol.

Manufacturing capabilities

- Turning, milling, drilling and thread cutting

- 3D freeform surfaces

- Ultra-precision high-gloss finishing

- 5-axis simultaneous machining

Processing of glass and composite materials

- Materials: glass, silicon, GRP and other materials on request

- Material thickness: ≥ 0.2 mm

- Polishing surfaces including surface metrology using Atomic Force Microscopy

- Dimension, form and position inspections

- Comparison to CAD model (Best-Fit)

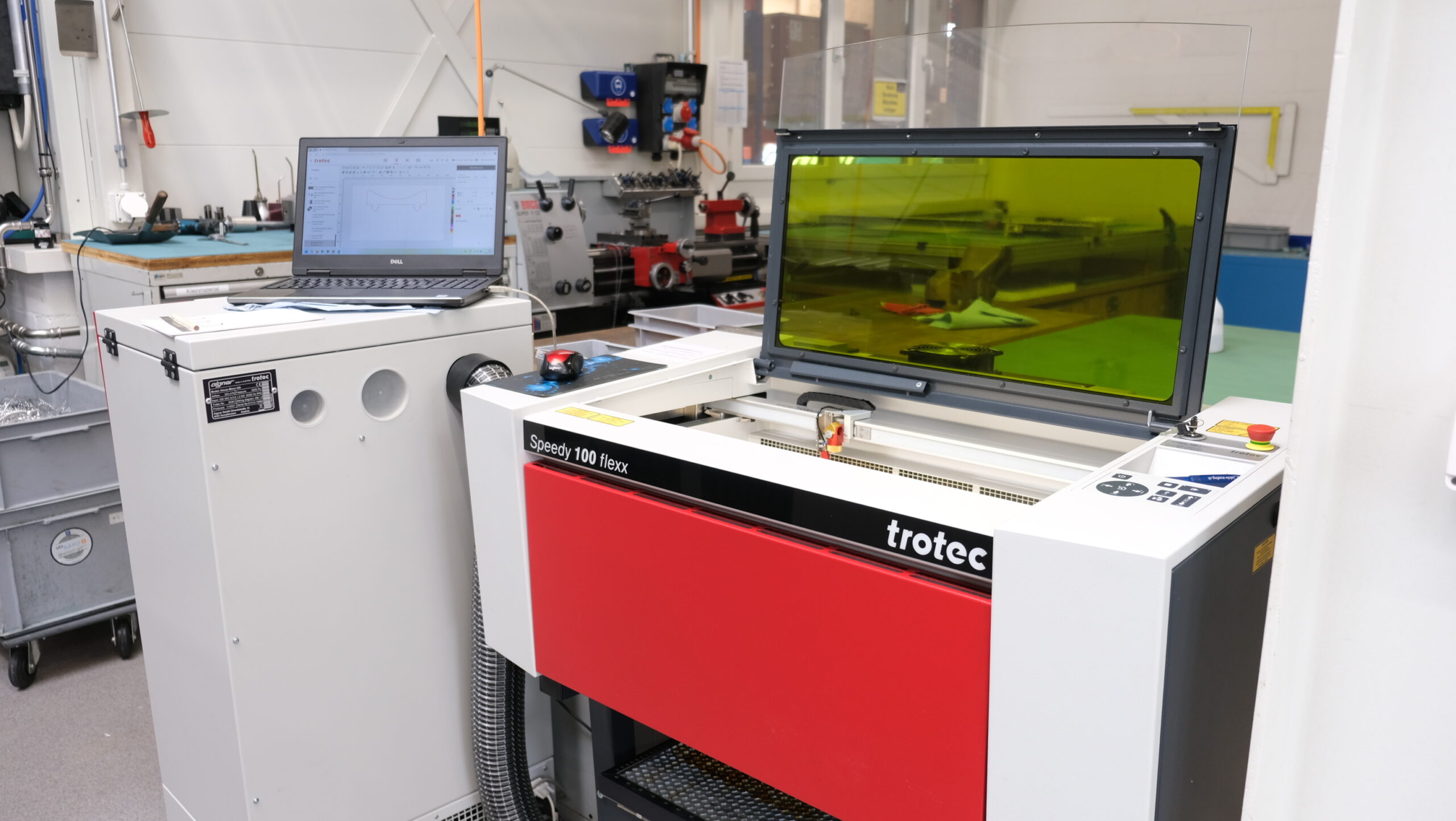

Labeling

- Laser marking

- Scales, parts & drawing numbers on glass and metals

5-axis milling machine

HERMLE C400

- Work space x/y/z: 850/700/500 mm

- NC swinging table: Ø 650 × 540 mm

- Max. Planning weight: 600 kg

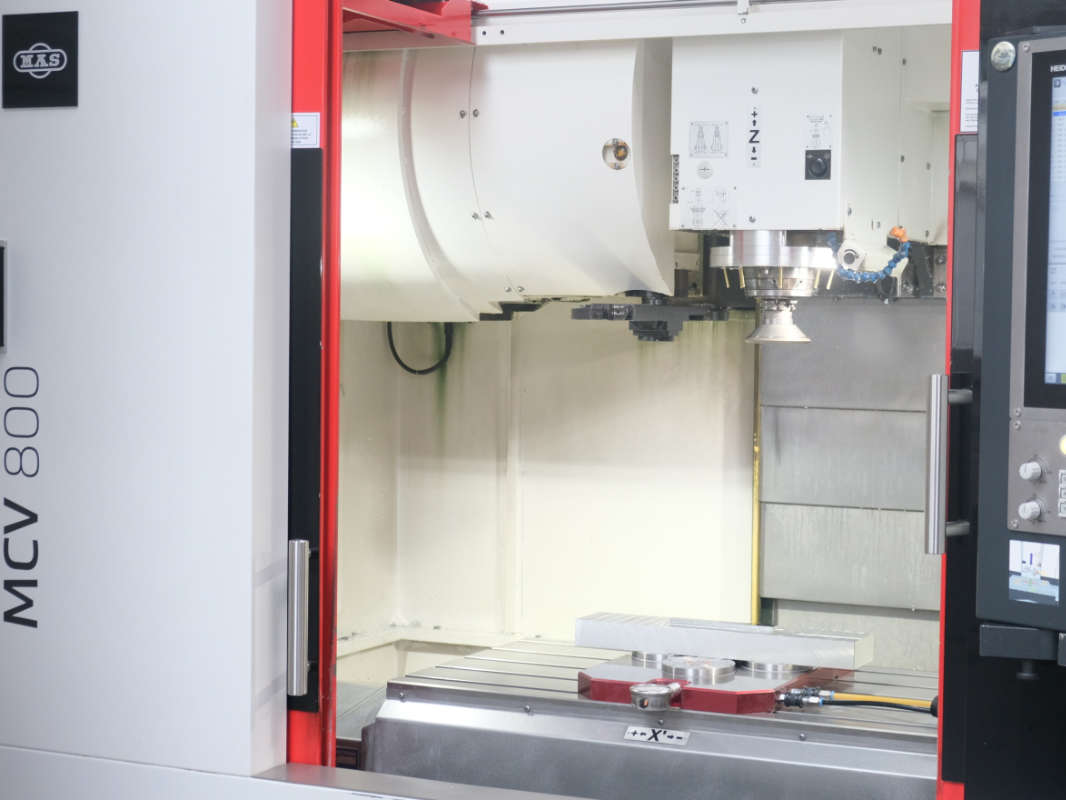

3-axis milling machine

MAS MCV 800 Quick

- Work space x/y/z: 800/500/500 mm

- Max. Planning weight: 500 kg

Software CAM

Mastercam

- Module: 5-axis simultaneous editing

- Import/export: Standard CAD formats