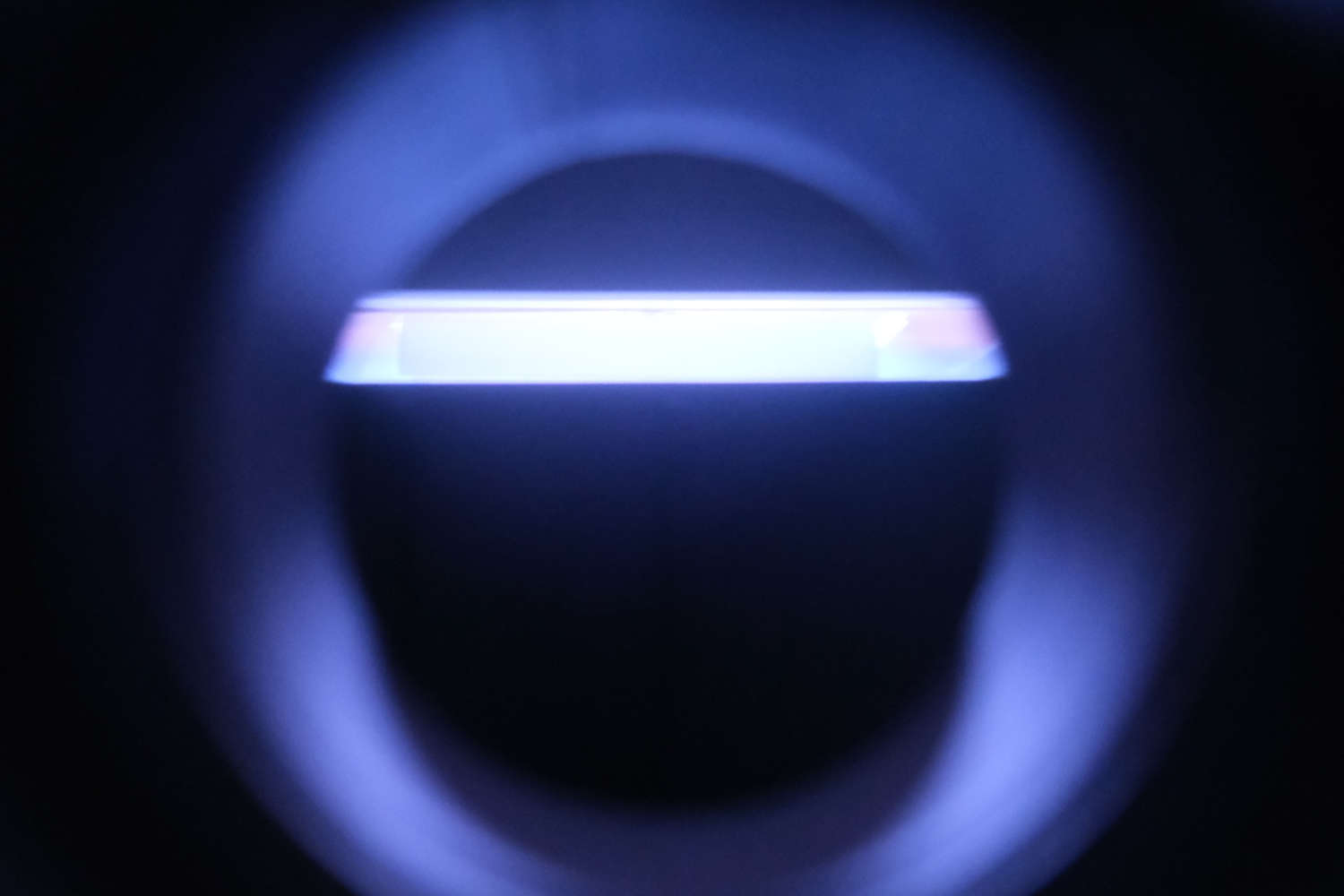

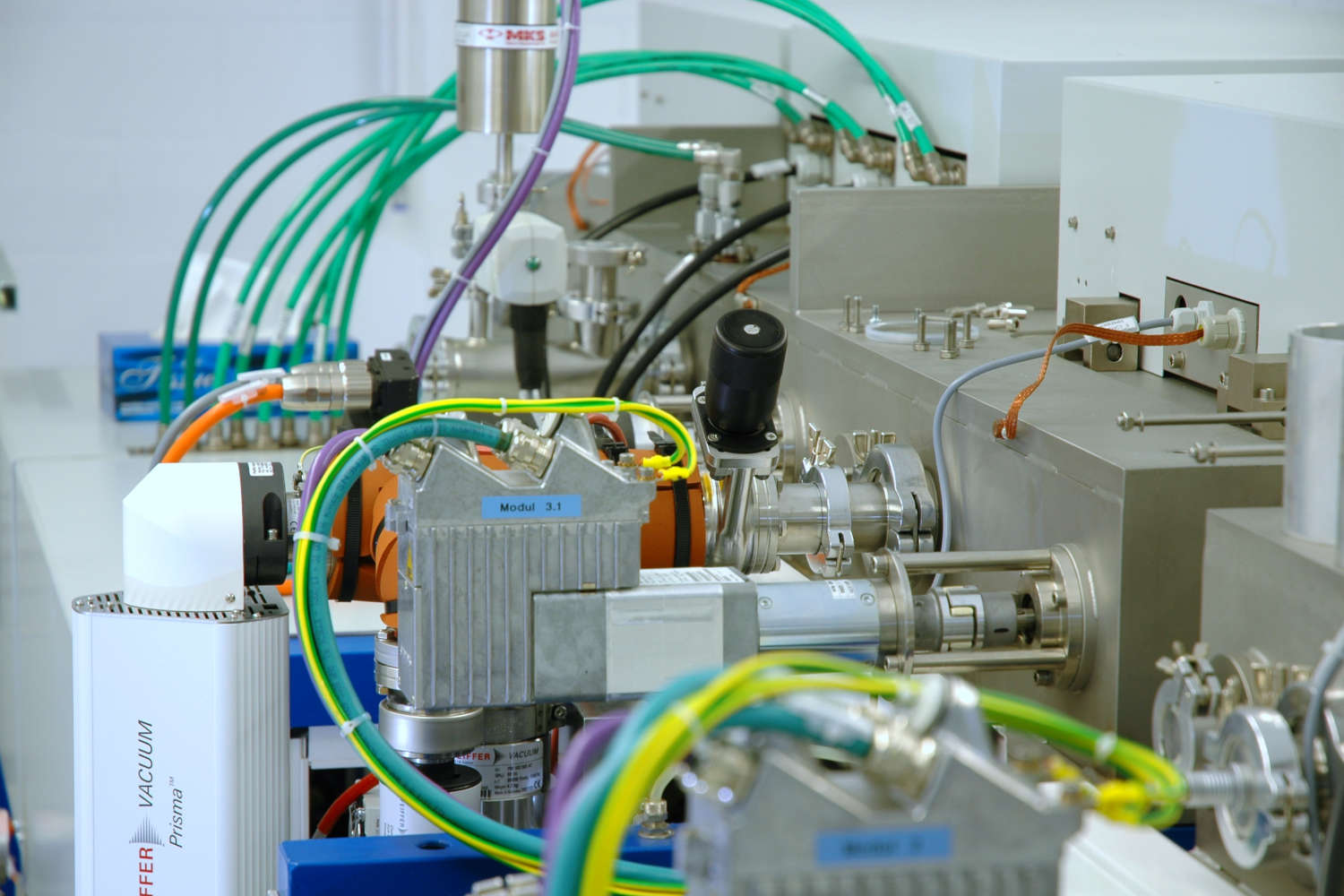

SwissNeutronics specializes in the preparation of neutron optical coatings using advanced DC magnetron sputtering techniques. This highly refined deposition process enables the creation of multilayer structures with exceptionally smooth interfaces, ensuring maximum neutron reflectivity. SwissNeutronics manufactures both non-depolarizing and polarizing supermirrors, achieving high m-values and outstanding performance in terms of reflectivity and neutron spin polarization.

SwissNeutronics is the leading provider of advanced neutron optical coatings, utilizing state-of-the-art DC magnetron sputtering technology. This precision deposition method enables the fabrication of multilayer structures with ultra-smooth interfaces, ensuring optimal neutron reflectivity and performance.

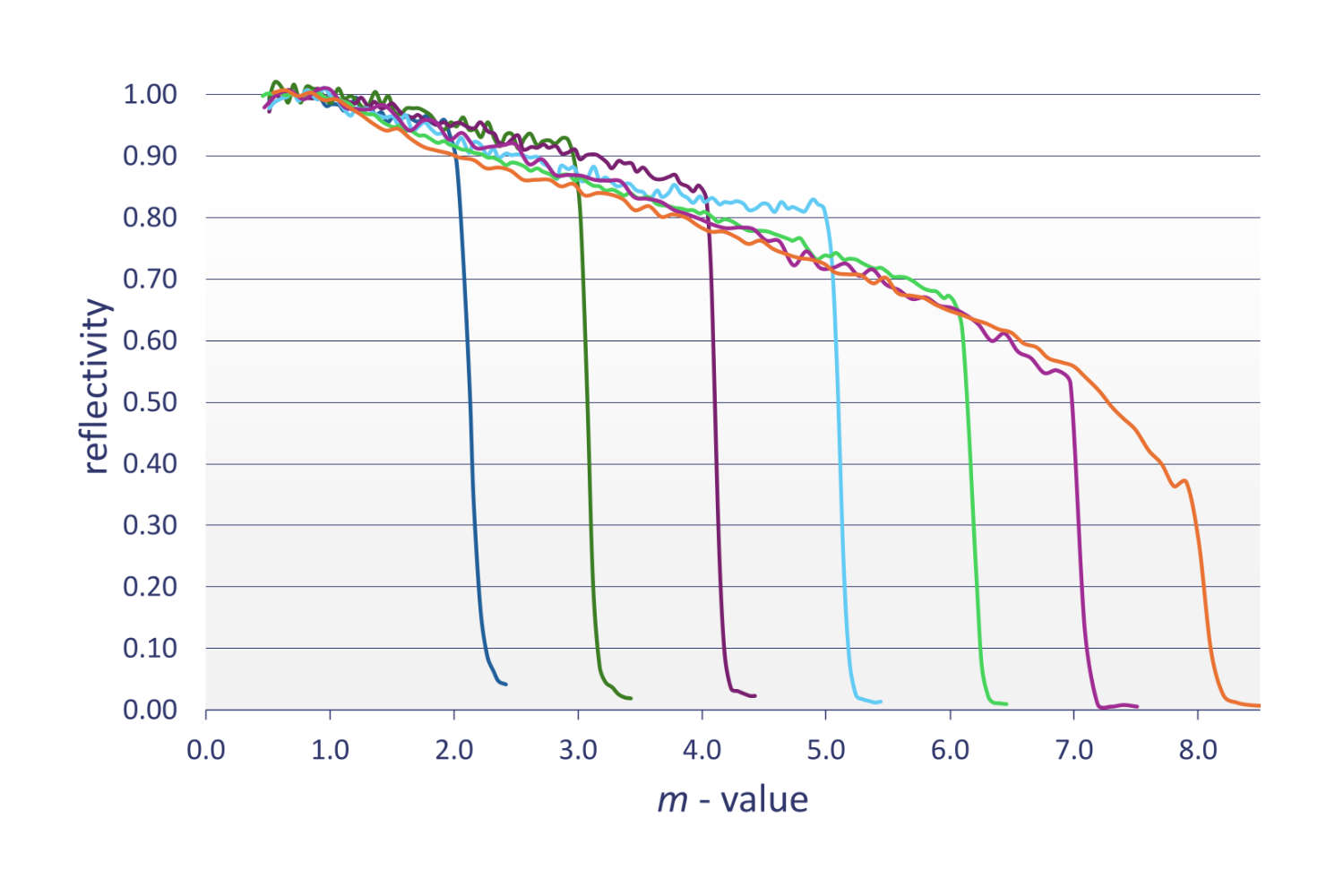

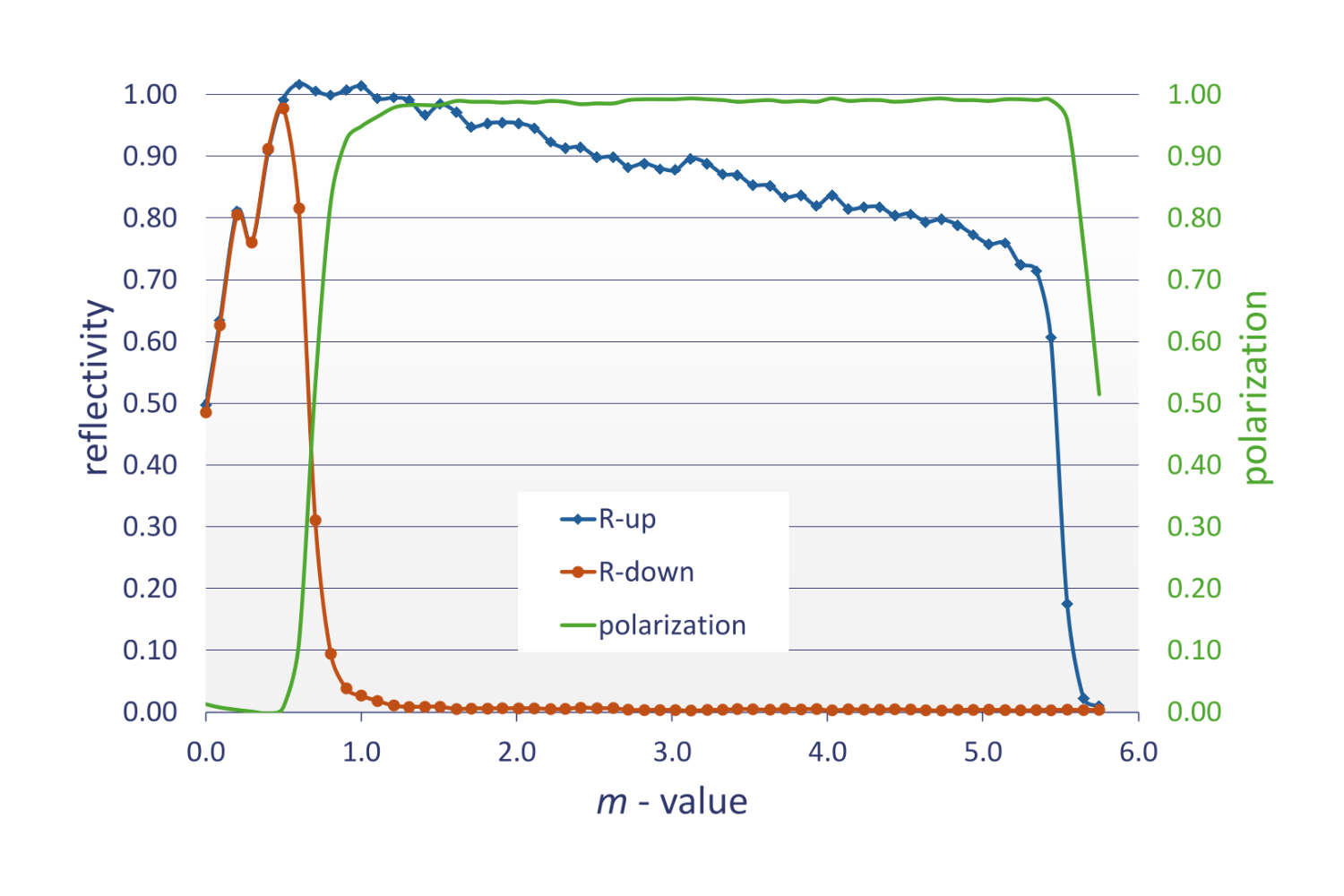

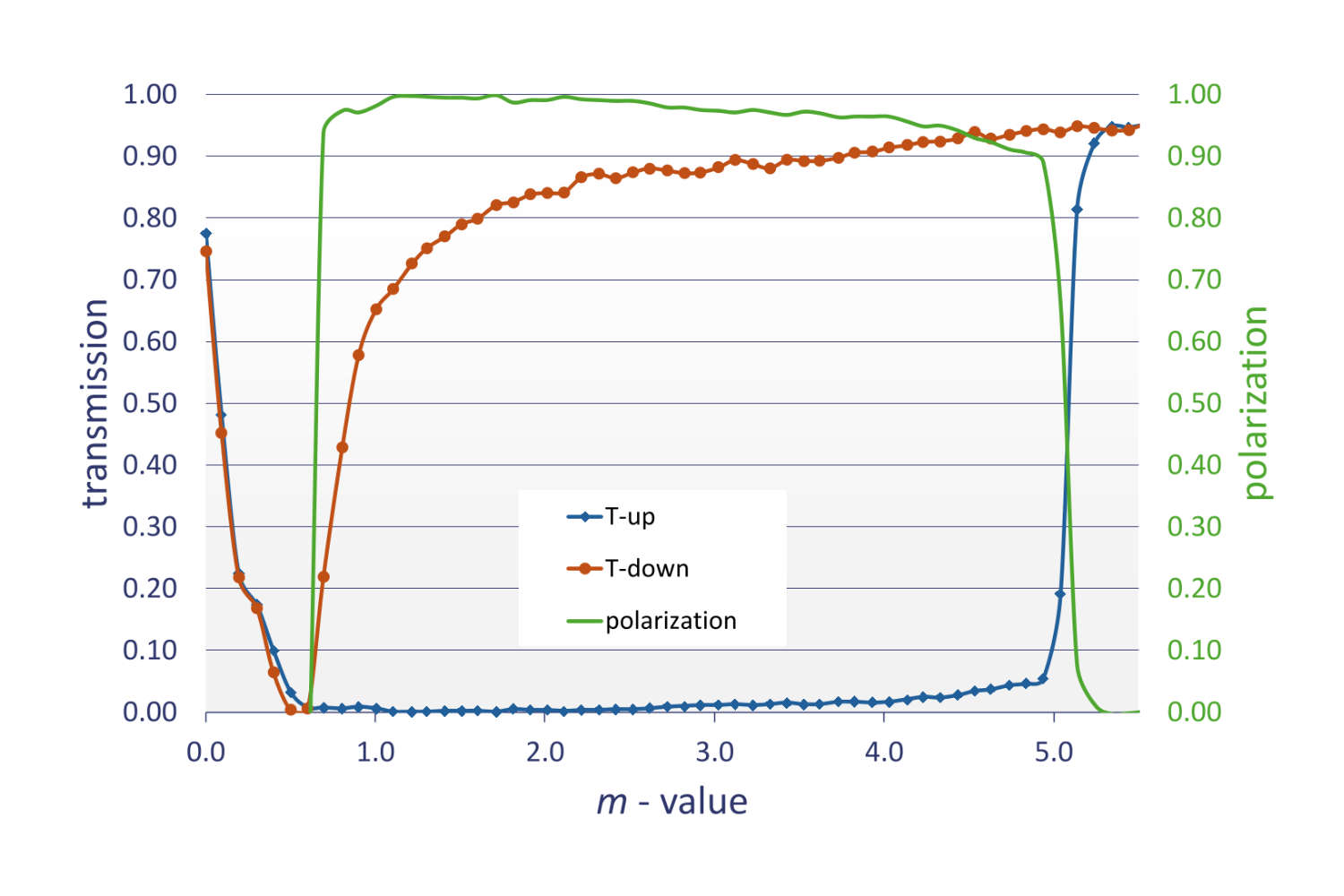

The company offers both non-polarizing and polarizing supermirrors, engineered to meet the highest standards in neutron optics. Its Ni/Ti supermirrors deliver exceptional reflectivity up to m = 8, setting a benchmark in non-depolarizing applications. Meanwhile, Fe/Si polarizing supermirrors achieve reflectivity up to m = 5.5, with neutron polarization nearing 100%, making them ideal for spin-dependent experiments.

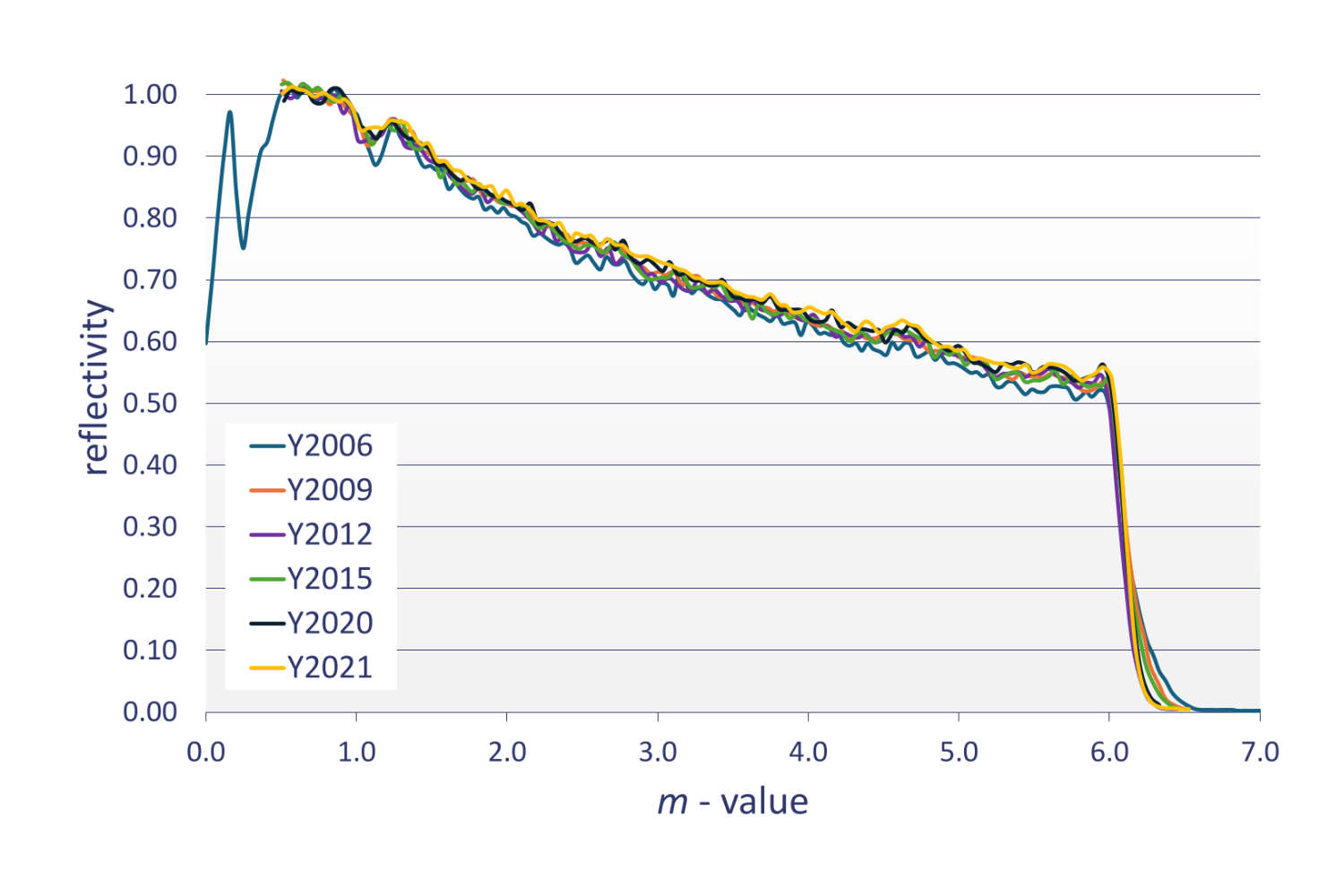

SwissNeutronics demonstrates proven expertise in large-scale fabrication, ensuring consistent quality and reproducibility across extensive surface areas. The coatings exhibit outstanding durability and long-term stability, even under intense radiation and demanding operational conditions. Additionally, the multilayer structures are designed with low internal stress, guaranteeing mechanical integrity and robust performance.

Technical highlights

- Ni/Ti Supermirrors

Exceptional reflectivity up to m = 8, setting a benchmark in non-depolarizing neutron optics. - Fe/Si Polarizing Supermirrors

High reflectivity up to m = 5.5, with neutron polarization approaching 100%, enabling precise spin-dependent applications. - Large-Scale Fabrication

Proven capability for highly reproducible production across large areas, ensuring consistent quality. - Durability & Reliability

Demonstrated long-term stability and radiation resistance, even under demanding operational conditions. - Mechanical Integrity

Engineered for low internal stress, supporting robust performance and structural stability.

Ni / Ti & non-depolarizing supermirrors

Fe / Si polarizing supermirrors

Reflectivity achieved during mass production

m-value |

Raverage |

Rbest |

P 1) |

| 2.0 | 93% | 95% | ≈0,99 |

| 3.0 | 89% | 91% | ≈0,99 |

| 4.0 | 80% | 82% | ≈0,99 |

| 5.0 | 72% | 76% | ≈0,99 |

| 5.5 | 70% | 75% | ≈0,99 |

1) Polarisation in reflection, determined at an applied field of H = 450 G

The reflectivity of an m = 6 supermirror, measured immediately after production in 2006, has been periodically monitored over the following years. These measurements consistently show no signs of aging or degradation, confirming the mirror’s long-term stability and reliability. This outstanding performance underlines the durability of SwissNeutronics’ coating technology, even after extended periods of use and environmental exposure.